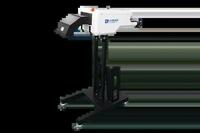

Print and Press-Apply Labeling System PLS540

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Place Of Origin

- China

- Minimum Order

- 1

- Packaging

- Carton ,pallet

- Delivery

- 30days

Specifications

Introduction Of Print and Press-Apply Labeling System PLS540

PLS500 Series print and apply label applicator systems is unrivaled regarding stability. It uses Zebra ZE500 printing engine and this engine is one of the most professional printing engines in the

world. The other structure used the most reliable Festo pneumatic part. With the design & development of BJT engineer, it is highly integrated design and spare part is modularized for fast

installment & maintenance. Warranty can be 5 years at most.

PLS500 Series print & label apply system can reach 60 times/min and with clear and readable barcodes.

With ergonomic integration design, you can replace labels and ribbons quickly, operator only needs less than 2 minutes to replace them.

Specifications Of Print and Press-Apply Labeling System PLS540

Model PLS540(Printing and Press-Apply Labeling System)

Labeling Accuracy ±1mm

Machine Size 740*562*386

Weight 50kg

Power 500W

Voltag AC220V

Air Consumption 110L/min @ 6bar

Material of Labe Coated paper/Sliver paper/Express bill(thermal paper)

Size of Label Width 25-107mm,Length 15-150mm

Type of Labe Thermo sensitive/Thermal transfer

Feeding Mode Label, fold labe

Diameter of Label Max 254mm(10inch

Diameter of Base Label Max 152mm(6 inch)

Roll Paper Diameter 100mm

Peel-away Spee Max 305mm/s(depend on type of printer engine and label)

Printer Port USB, Ethernet port, Parallel port

Labeling Trigger Mod Labeling/Printing( Changeable)

System Input Port Labeling/Printing

System Output Port Print task ready、Finished labeling、Error alarm

We also have types of Paper Void Fill Machine for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2014

- Address:7F,11th Building,West Area,Chinese Artificial Intelligence

- Contact:lockedair com

Other products from Hangzhou Bing Jia Tech. Co., Ltd

Relate products of Print and Press-Apply Labeling System PLS540

Print and Press-Apply Labeling System PLS540

Introduction Of Print and Press-Apply Labeling System PLS540 PLS500 Series print and apply label applicator systems is unrivaled regarding stability. It uses Zebra ZE500 printing engine and this engine is one of the most professional printing engines in the world. The other ...