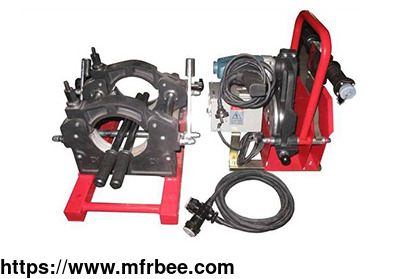

Butt Welding Machine

Product Quick Detail

- FOB Price

- USD $800.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Features of Butt Welding Machine

Butt Welding Machine is suitable for butt fusion of plastic pipes made of PE, PP, and PVDF material. It has Certification of CE and ISO. The color is red or customized. Applicable Materials: PE,

HDPE, PP, PVDF, PPR, PB. After-sales Service Provided: Engineers available to service machinery overseas. Butt Fusion Welding Machine is an industrial machine that is extensively demanded for

welding purposes. It works by melting two ends of the plastic or metal and then pressing them onto each other until they get a weld. Our product range is known for providing a tight bond between

two broken pieces of metal or plastic.

With its own fusion welding machine manufacturer , Plaswelding is a professional plastic pipe welding machine manufacturers and plastic pipe welding machine suppliers in China that has various

reliable plastic pipe welders for sale including pe butt welding machines, PVDF welding machines, pp pipe welding machines, HDPE pipe welding machine, etc. We can also offer manual china butt

welding machine, hydraulic butt welding machine, and other butt fusion welders. If you want to know more about the China automatic welding machine, please contact us now!

What is the difference between hdpe, pp pipe and pvdf welding machine?

Welding is the process of joining together by heating and softening the surface. Pipe saw uses the same way when cutting pp, pe and pvdf plastic fittings.They are all cut using saw strips. When

welding thermoplastics, one of the key components is the material itself. In order to get strong and durable welds, it is necessary to make sure that your substrate and electrode are the same. Here

are some tips for welding different types of plastics and steps to ensure proper welding.

Welding polypropylene

Polypropylene (PP) is one of the most easily welded thermoplastics and has many different uses. PP is the most stable polyolefin in size due to its excellent chemical resistance, low specific

gravity and high tensile strength.

Welding polyethylene

Another thermoplastic that is fairly easy to weld is polyethylene (PE). Polyethylene has the advantages of impact resistance, excellent wear resistance, high tensile strength, processability and

low water absorption.

The most important thing for welding polyethylene is that it can be welded from low to high, but not from high to low. Because the higher the density, the more difficult it is to decompose the

components to be welded.

If these parts cannot be disassembled at the same speed, they cannot be connected smoothly.

Types of Butt Welding Machine for Sale

Welding is the process of joining together by heating and softening the surface, and Plaswelding has various reliable butt fusion welding machines for sale, .

Hydraulic Butt Welding Machine

LHY 160 Hydraulic Butt Welding Machine

LHY 250 Hydraulic Butt Welding Machine

LHY 315 Hydraulic Butt Welding Machine

LHY 450 Hydraulic Butt Welding Machine

LHY 630 Hydraulic Butt Welding Machine

LHY 800 Hydraulic Butt Welding Machine

LHY 1000 Hydraulic Butt Welding Machine

LHY 1200 Hydraulic Butt Welding Machine

LHY 1600 Hydraulic Butt Welding Machine

LHY 2000 Hydraulic Butt Welding Machine

LHY 2500 Hydraulic Butt Welding Machine

Hydraulic Butt Welding Machine

Butt Welding Machine is suitable for butt fusion of plastic pipes made of PE, PP and PVDF materials. It has Certification of E and SO The color is red or customized.

Manual Butt Welding Machine

LHM 160 Manual Butt Welding Machine

LHM 200 Manual Butt Welding Machine

Manual Butt Welding Machine

LHM Series Manual butt welding machines are suitable for PE & PP pipes and fittings on the building site and in the factory, with high quality aluminum casting without compromising strength.

With its own plastic welding machine factory, Plaswelding is a professional plastic pipe welding machine manufacturer and supplier in China that has various reliable butt fusion welding machines

for sale, including pe butt welding machines, PVDF welding machines, pp pipe welding machines, HDPE pipe welding machine, etc. We can also offer manual butt welding machine, hydraulic butt welding

machine, and other butt fusion welders. If you want to know more about the China automatic welding machine, please contact us now!

What is the difference between hdpe, pp pipe and pvdf welding machine?

Welding is the process of joining together by heating and softening the surface. Pipe saw uses the same way when cutting pp, pe and pvdf plastic fittings.They are all cut using saw strips. When

welding thermoplastics, one of the key components is the material itself. In order to get strong and durable welds, it is necessary to make sure that your substrate and electrode are the same. Here

are some tips for welding different types of plastics and steps to ensure proper welding.

Welding polypropylene

Polypropylene (PP) is one of the most easily welded thermoplastics and has many different uses. PP is the most stable polyolefin in size due to its excellent chemical resistance, low specific

gravity and high tensile strength.

Welding polyethylene

Another thermoplastic that is fairly easy to weld is polyethylene (PE). Polyethylene has the advantages of impact resistance, excellent wear resistance, high tensile strength, processability and

low water absorption.

The most important thing for welding polyethylene is that it can be welded from low to high, but not from high to low. Because the higher the density, the more difficult it is to decompose the

components to be welded.

If these parts cannot be disassembled at the same speed, they cannot be connected smoothly.

FAQs of China Butt Welding Machine

Q.What materials are the butt welding machines capable of welding?

A.

PE, HDPE, PVDF, PPR, and so on.

Q.What welding is used for butt joints?

A.

Butt welding refers to the method that the weldment is respectively placed between two clamping devices to make its end face aligned, and the electric heating is applied at the contact point for

welding. For butt welding, the cross-section size and shape of the contact part of the weldment shall be the same or similar, so as to ensure the uniform heating of the contact surface of the

weldment. Butt welding is mainly used for manufacturing closed parts (such as bicycle rim, steel window, etc.); Rolling material lengthening (such as steel town, steel pipe, steel bar, etc.);

Welding of dissimilar materials (such as butt welding of dissimilar materials for saving valuable materials and improving the service life of tool working parts). Butt welding is widely used

because of its high productivity and easy automation.

Q.What's the principle of butt fusion welding machine?

A.

So-called fusion welding refers to the welding process, the welding joint in the action of high temperature to the melting state. Since the welder parts are closely attached together, the melting

liquid of the two parts will be mixed without pressure under the action of the temperature field and gravity. After the temperature is reduced, the melting part condenses, and the two workpieces

are firmly welded together to complete the welding method.

As one of the most professional plastic pipe welding machine suppliers, we provide china plastic pipe welding machine, pe pipe fusion welding machine, china plastic pipe welding machine and etc.

Want to know more? Contact us.

- Country: China (Mainland)

- Founded Year: 2017

- Address: No.35, Shaotang Road, Outang Education Park, Wuxi

- Contact: plaswelding .com