|

Product Name

|

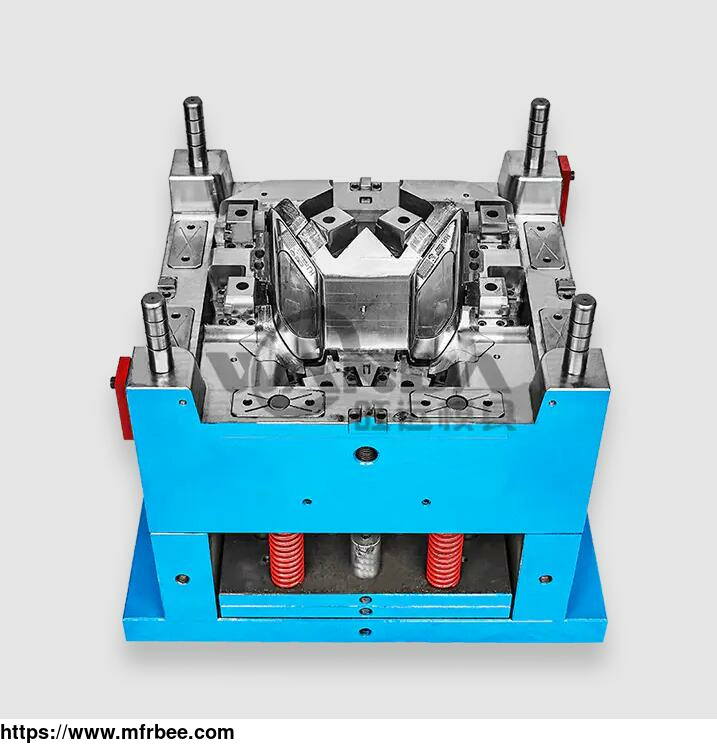

Auto Parts Mould

|

|

Brand

|

Wanda Mould

|

|

Model

|

No specific Model

|

|

Material

|

S136/H13/718H/2738/P20/S50/C45

|

|

Quality Control

|

Supporting original parts standard

|

|

Product Range

|

Automotive interiors, exteriors, and all injection molded products

|

|

Provide Services

|

Answer all requests and answers

|

|

Surface Treatment

|

Mirror polished/skin texture

|

|

Material Temperature Range

|

Determine the temperature range according to the characteristics of different products

|

|

Shape

|

No fixed shape

|

|

Specification

|

No specifications

|

|

Features

|

The characteristics of the mold require high precision, complex structure, multiple processing procedures, long service life, safe, convenient operation, and easy maintenance.

|

|

Application

|

Molds are widely used in machinery, electronics, automobiles, information, aviation, aerospace, light industry, military industry, transportation, building materials, medical,

biological, energy and other industries. About 60%-80% of parts and components need to rely on mold processing.

|

|

Shaping mode

|

Injection molding

|

|

Process Combination Type

|

Combining the product process requirements, a set of cavity-shaped structural components are composed of a male mold and a female mold, and plastic products are made through

injection-cooling-molding

|

|

Number of Cavities

|

According to the product setting

|

|

Plastic Material

|

PP/ABS/PC/HDPE/LDPE/PA66/POM/TPR

|

|

payment Terms

|

Receive 30% deposit to start the project, and pay 70% of the balance for delivery after mold acceptance

|

|

Minimum Order Quantity

|

Unlimited

|

|

Supply Capacity

|

40-60 molds per month

|

|

Applicable Machine

|

Any model

|

|

Mold Material

|

S136/H13/718H/2738/P20/S50/C45

|

|

Runner System

|

YUDO/HANS/HTS/MINGYANG

|

|

Product Details

|

CAD/3D

|

|

Whether to Accept the Sample, Whether the Sample is Free

|

Accept samples

|

|

Sample Delivery Time

|

According to the processing progress of the project

|

|

Can the Product be Customized

|

Can

|

|

Packing Details

|

Fumigation-free compressed board packaging

|

|

Product Advantages

|

Stable and reliable quality,

|

|

Delivery Control

|

Control within a reasonable delivery period

|

|

Industry Experience

|

More than 15 years of professional experience in the same industry

|

|

Processing Capacity

|

Have the processing capacity to fully meet customer orders

|

|

Mold Accuracy

|

Strictly control dimensional accuracy, shape accuracy, position accuracy, and surface accuracy

|

|

Rapid Production Technology

|

The company has rapid production technology

|

|

Manufacturing Process

|

1. Accept the task 2. Mold design 3. Mold manufacturing 4. Mold inspection and test mold 5. Modification and mold repair 6. Mold maintenance

|

|

After-sales Service

|

Do reliable mold quality and considerate service

|