Kailite Plastic Extrusion Machinery

Product Quick Detail

- Minimum Order

- 5

- Place Of Origin

- China

- Packaging

- Stretch film and distillation plate

- Delivery

- 45 Days

Specifications

Plastic extrusion is defined as a manufacturing process (high-volume), in which the raw plastic / raw plastic material is melted and then formed in a continuous profile. With this process, various products can be manufactured such as pipe/tubing, window frames, weather stripping, wire insulation, and adhesive tape. In general, the plastic materials that are used in the process of extrusion are Polyethylene, Polypropylene, Nylon (Polyamides), Polystyrene, Polycarbonate, Acetal, Acrylic, and Acrylonitrile Butadiene Styrene (ABS). These are just the primary plastic materials that are extruded. Apart from these, there are many other plastic materials that can be/are extruded all around

Plastic Extruder Machine Manufacturer

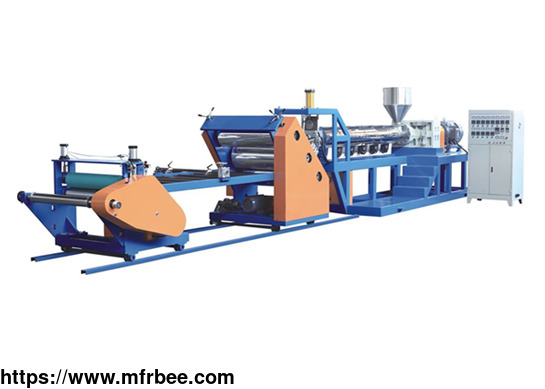

The production line mainly produces pipe material, special-shaped material and sheet material. The unit consists of high speed and high-efficiency extruder, vacuum shaping equipment, tractor, cutting machine.

Cheap Plastic Extruder Machine Manufacturer

Conical single/twin-screw extruder machine has the advantages of high automatization, stable working performance, large output and high efficiency, can be used for most of the plastic pipes, profiles, etc.

Extrusion line Auxiliary Equipment

SWP Series Crusher

Automatic Drying And Feeding Machine

PE Physical Foamed Pipe/Stick Machine

SRIE-Z Series Mixing Machine Unit

Electrical Control System

FAQs of Plastic Extrusion Machinery

Q

What is an extrusion machine?

A.

Extrusion machines force or pull unformed material into alignment guides and shaped dies to produce lengths of stock forms and cross-sectional shapes. They are used mainly in the plastics, metals, and composite-forming industries. Extrusion machines are also used in automotive, aerospace, and construction applications.

Q

What is extrusion process in plastics?

A.

Extrusion is a continuous process of converting a solid plastic mass, pellet or powder into a melted form where it is pushed through a die into a shape. This shape is then moved through various secondary operations where it is cooled then cut, coiled or experiences a variety of other possible operations.

Q

What kind of plastic is best for extrusion or molding?

A.

Commodity plastics are suitable for most applications and account for 90% of all thermoplastic use. They are readily available, easy to process, and the least expensive plastic for extruded products. Examples of commodity plastics include polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC).

Q

What is extrusion process?

A.

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section. The extrusion process can be done with the material hot or cold. Commonly extruded materials include metals, polymers, ceramics, concrete, modelling clay, and foodstuffs.

Q

What is the difference between extrusion and injection molding?

A.

Injection moulding forms three-dimensional shapes. The injection moulding process is based on the molten die-casting method. In the extrusion method, the finished products have a two-dimensional form which is continuous in length and can be cut to multiple lengths and punched or notched.

Qingdao Kailite plastic machinery Co., LTD. is a high-tech joint-stock enterprise integrating scientific research, development, production and management of plastic extrusion and plastic products and technical services.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia,Middle East,Oceania

- Founded Year: 2016

- Address: B-9, No. 398, Jiaozhou West Road, Zhongyun Industrial Second Park, Jiaozhou City, Qingdao

- Contact: Peter Tai