Modular Formwork

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Suzhou, Jiangsu Province, China

- Packaging

- By pallet

- Delivery

- 20-45 days after deposit

Specifications

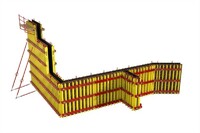

TECON Modular Formwork mainly consists of AluLITE Formwork, Steel LITE Formwork and Plastic Formwork TP60+.

For any villa project, a low-cost housing project, especially with hundreds of or thousands of houses at the same plan and size, modular formwork for concrete can maximize site productivity and

greatly save labour costs.

On some occasions, even with conventional building methods such as bricks and concrete hollow blocks and others., build with rebar and concrete via modular formwork will still benefit you from lead

time and total cost per house though the initial investment seems higher than traditional bricks and timbers.

Modular formwork can build wall and slab separately and build wall and slab together in one time pour with customized formwork planning and fabrication. Very timber and even no skilled workers are

needed due to their easy to learn assembly sequence.

Advantages of Modular Formwork

The modular formwork system is designed with standardized panels and components to reduce or limit cutting materials on site. This speeds up the entire process and therefore reduces on-site labour.

They can also be interchanged with conventional methods. Commercial, civil, and industrial contractors can replace the traditional methods of cast-in-place concrete engineering by using modular

formwork systems and quickly achieve one-time casting, thereby minimizing the financial expenditure of labour and materials. By choosing to lease, contractors can gain more benefits in reducing the

costs associated with regular procurement. Once the work is completed, this also eliminates the need to recover the purchase cost by reselling the materials.

As one of the most professional formwork accessories suppliers , we provide modular shuttering, modular formwork system, concrete formwork accessories and etc. Contact us to know more about metal

formwork system.

- Country: China (Mainland)

- Founded Year: 2013.11.13

- Address: Room1105-1110, Block A, Building 2, LEFO Commercial Center, Wuzhong District, Suzhou, Jiangsu Province, China

- Contact: Edgar Chow