E-Grind Superabrasives Product

Specifications

E-Grind offers a full range of superabrasive : Synthetic diamond, Cubid Boron Nitrid and related Solid products like CVD, TSP, PDC, PCD&PCBN, Diamond Wire-Draing Die blanks, for Drilling,

Sawing, Cutting, Grinding, Honing, Lapping, Polishing and Finishing processes, in the industries of Machinery, Stone, Constructon, Automobile, Electronics, Aerospace etc. Our profession enable us

to provide the highest performance products for superabrasives industry. E-Grind ensures the products consistency from lot to lot by our advanced lab and experienced engineers. Look forward to the

nice cooperation with you in our superabrasives products.

Types of Superabrasives Product

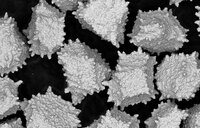

Diamond PowderDiamond Powder

E-Grind provides a full range of synthetic diamond powder, with polycrystalline, mono crystal, including resin bond diamond, metal bond diamond, saw grit and wheel grit series, widely used for

carbide, ceramic, glass, non-ferrous Metal.

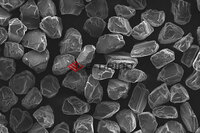

CBN PowderCBN Powder

E-Grind supplies all types of CBN, with black, amber, brown and golden color, to meet the grinding needs of various ferrous materials, such as cast Iron, high speed steel, alloy steel, super

alloys.

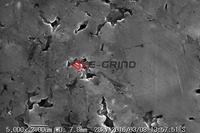

Coated Diamond / CBNCoated Diamond / CBN

E-Grind provides a variety of diamond & CBN metal clading materials (Titanium Nickel Cobalt Silicon clading, etc.), which greatly increases the china abrasives holding power, wear resistance, and

conductivity.

Diamond & CBN Solid ProductDiamond & CBN Solid Product

E-Grind offers various solid products, such as CVD for dressing tools, PCD, PCBN blank for cutting tools, and mining, oil grade PDC, etc.

What is Superabrasives?

Superabrasives include Synthetic Diamond and cubic boron nitride( CBN)powder. Industrial synthetic diamond powder are mainly made through the high temperature and high pressure method, convert

carbon into diamond, and convert hexagonal boron nitride into cubic boron nitride. Covalent bonds are formed between atoms to form a stable tetrahedral structure, so the superabrasives has stable

chemical properties, high wear resistance, high temperature resistance, acid resistance, alkali resistance, non-magnetic, poor conductivity etc. As the two hardest substances in nature, diamond and

CBN have been widely used in ultra-precision grinding, high-efficiency grinding, and grinding of difficult-to-machine materials.

Classification of Superabrasive

The appication of Diamond and CBN abrasives, due to their complementarity in the adaptation of processing materials, greatly expand the processing range of the abrasive tools made of them, covering

almost all processed materials including various high-hardness, high-brittle, high-strength and toughness materials. Compared with convenient abrasives, super abrasives has the advantages of long

grinding life, high smoothness, high grinding efficiency, and environmental protection etc.

01

Cubic Boron Nitride Abrasive

The emergence of CBN abrasives has led to a revolution in grinding technology. It can withstand high temperatures of 1300℃~1400℃, is chemically inert to iron group elements, has good thermal

conductivity, high removal rate when grinding steel, high grinding ratio, and abrasive tools. Long life, it is the best abrasive for grinding hardened steel, high-speed steel, high-strength steel,

stainless steel and heat-resistant alloys with high hardness and toughness.

02

Diamond abrasive

Diamond abrasive tools are the best abrasive tools for grinding hard alloys, optical glass, ceramics and other hard and brittle materials, but because they are easily carbonized at 700℃~800℃, they

are not suitable for grinding steel materials and ultra-high-speed grinding.

We have types of pcd diamond cutting tools for sale, if you have interest, please contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas,European Union

- Founded Year: 450000

- Address: Room 1841, Tower A, Wanda Plaza, 171#, Zhongyuan Road, Zhengzhou City, Henan Province, China

- Contact: locke liu