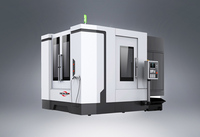

From the vertical type and horizontal type to gantry type, Sealion Machine Tool offers you a wide range of CNC Machining center China . With our hard-working design engineers, we always keep our

best machining center above other manufactures. Those machines are widely used in mold processes, general machining, and massive production area. It can be singly used and can be used for multiple

operations on parts in a production line. Those machining centers are powerful, high-speed positioning, mechanical and electrical integration, and equip with automatic chip conveyor. Please talk to

our professional engineers for selecting the best CNC precision machining, high precision CNC milling machine, and high-speed CNC milling machine.

Cnc Machining Center Working Principle

After the workpiece is clamped in the machining center, the CNC system can control the cnc milling tools according to different machining processes, automatically select and replace the cnc milling

machine tools, automatically select the speed of the machine spindle, the feed speed, the motion path of the tool relative to the workpiece, and other auxiliary functions and machining a workpiece

can be accomplished in multiple processes. It has a variety of cutters or cutter selection functions, which greatly improves the production efficiency.

Due to the centralized and automatic tool change process, the machining center reduces the clamping of the workpiece. Measurement and machine tool adjustment time make the cutting time of the

machine tool reach 80%% of the machine start time (ordinary machine tool is only suitable for 15 times). It also reduces the working process turnover, loading and unloading and storage time between

workpieces, shortening the production cycle, and has obvious economic benefits. The cnc milling center is suitable for small and medium batch production with complex shapes, high precision

requirements, and frequent product replacement.

Benefits of Cnc Machining Center

1.Fully enclosed protection

2.Using multiple tools that are automatically exchanged

3.The process is concentrated and continuous

4.High automation, high precision and high efficiency

5.Multiple workbenches are used, and the workbenches are automatically exchanged

6.Powerful, tending to compound processing

7.The best benefit is that cnc milling center can be achieved under appropriate conditions

8.High degree of intelligence, complex structure, powerful function

Turning Center vs Machining Center

Traditional turning center have a horizontal structure. It has a main shaft and a workpiece placed parallel to the floor. The spindle is installed on the spindle box facing the tailstock, which is

located at the other end of the worktable. On the other hand, machining centers tend to have a vertical style. It has a workpiece fixing system installed on the base of the machine tool, and a

cutting tool suspended above the worktable for machining the workpiece from the top.

Likewise, these modern CNC machines usually have multi-axis machining capabilities, which allows them to cut workpieces at different angles and in different directions. In order to integrate all

functions into one machine, the style of the turning center and the machining center has evolved into a booth-like chamber containing all electric tools. Since the turning center follows the basic

design of the lathe, the length of the machine tool may be larger than that of the machining center.

Sealion Machine Tool is a professional vertical machining center manufacturers in china , we provide machine tools China, chinese machine tools, 2 axis mill, best lathe machine and etc. Want to

know more?Please contact us.