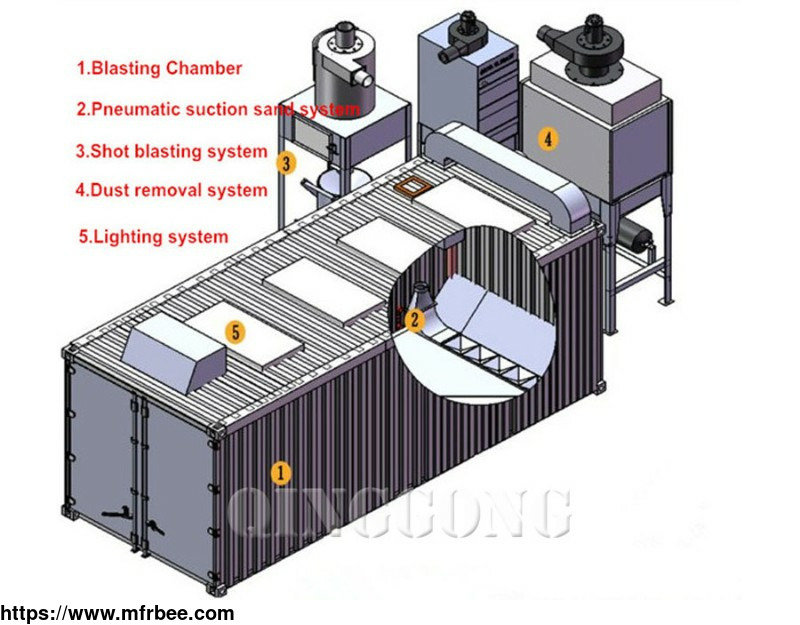

AIR BLAST ROOM

Specifications

Air blast room or Air blasting cabinet with pneumatic media reclaim system – An economical alternative, vacuum reclaim systems utilize cyclone separators to recover usable media to the blast

machine, while dust and broken-down media are drawn out into the dust collection system.

The media is vacuumed up, cleaned and returned to the blast pot. The system automatically cleans recyclable abrasives, through the use of a cyclone separator, and returns the clean, good media back

to the blast machine. Also known as sweep-in or pneumatic recovery systems, Qinggong Vacuum Reclaim Systems rely on the use of cyclone separators and work best with lighter abrasives such as glass

bead, aluminum oxide, garnet or plastic.

We have air blasting machine and blast room for sale.

Feature of our Air Blast Room Cabinet:

Heavy gauge steel enclosure

Fluorescent lighting above and outside the enclosure

Safety door interlocks

Mandoor and viewing window

Emergency light glass – above man door

Full floor recovery

Bar grating rated at 2000 lb per sq. Ft. uniform loading

Reclaim separation system with debris screen

Cartridge ventilation dust collector with automatic pulse jet filter cleaning

Siemens12 control panel

Floor Sections To Transition

Dust Collector For Air Blasting Equipment

The dust collection system is of Qinggong own design and manufacture. It is dry air system with continuous on-line filter cleaning. The system is supplied with an appropriately sized high capacity

exhauster, pneumatic and electrical controls. The system is designed and built for efficient operation and is the result of years of research and experience in dust collection systems for the

abrasive blast cleaning industry.

If you want to know more types of shot blasting supplies, please contact us.

As one of shot blasting machine manufacturers, we will provide more types of related products for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Emerging Markets

- Founded Year: 1975

- Address: No 377, Langyatai S Rd, Huangdao District, Qingdao City, China

- Contact: QGMA .com