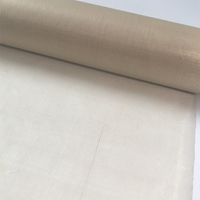

0.05mm Peel Ply Release Fabric

Product Quick Detail

- FOB Price

- USD $10.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Taixing

- Packaging

- Export carton

- Delivery

- within 7 working days

Specifications

0.05mm Peel Ply release fabric, nonstick surface, quick heat transfer, not easy to wrinkle when pressing

The Detail of 0.05mm Peel Ply Release Fabric

Nonstick peel ply release fabric is also called PTFE coated fiberglass, made by special peel ply fiberglass in thickness of 0.02mm, then coating PTFE on both sides to reach thickness to 0.04mm. The

impregnating process of this high temperature peel ply fabric

The Advantage of 0.05mm Peel Ply Release Fabric

High and low temperature proof

Smooth friction performance

High mechanical strength

Non stick surface, quick releasing

Good thermal insulation to 260℃/500℉

Flame retardant

Quick heat transfer

Light weight

The Applications of 0.05mm Peel Ply Release Fabric

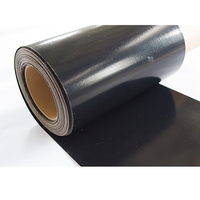

Polyethylene film products production, like CPE glove

0.05mm release fabric is designed for automatic high speed gloves sealing and cutting machine as release sheet, the fabric is very thin to provide quicker hot transfer and not easy to wrinkle when

pressing. We also have 0.03mm release fabric available if you need thinner one.

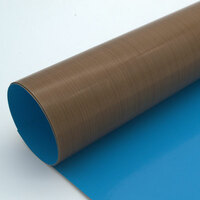

Aerospace industry for curing

PTFE coated fabrics in thickness of 0.04mm can be made porous and used in aerospace industry, people in this industry call this fabric peel ply alternative, light content of PTFE increase

permeability to allow excess resin, volatile and trapped air to escape into the breather during curing while maintain its quick release property

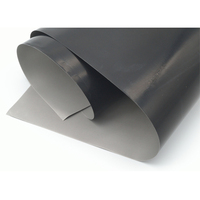

Electronic industry like CCL, FPCB laminating

With the coming of 5G wireless systems, 0.04mm PTFE coated fiberglass fabric become a new material to make PTFE CCL by laminating several layers fabric together, the material offers better

dielectric property, and has obvious advantages in the high frequency circuit board.

As one of peel ply suppliers, we have types of related products for sale, if you have needs, please contact us.

If you want to know more types of heat resistant fabric solutions, please visit our website.

- Country: China (Mainland)

- Address: No.2 Junmin Road, Urban Industry Park, Taixing, Jiangsu, China

- Contact: Mutiflon