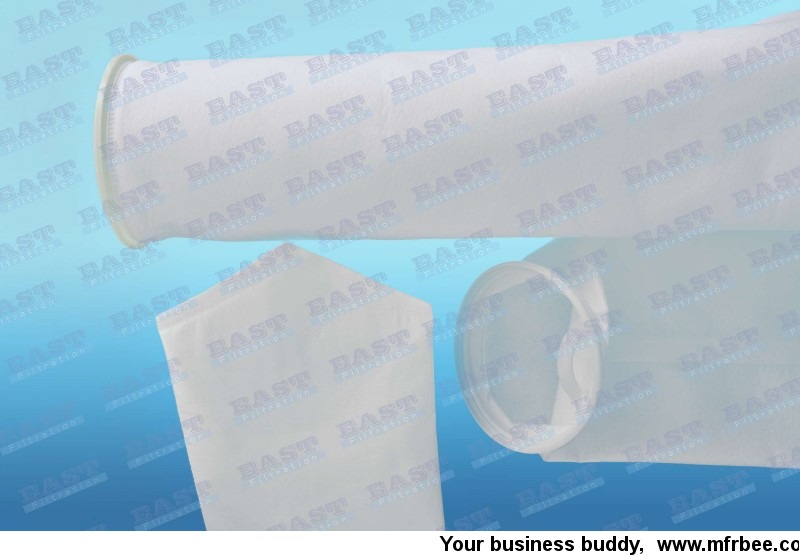

filter bag

Product Quick Detail

- Bag Filter

- filtration

- China

- filter bag

- Packaging

- 50 pcs per box

- Delivery

- 30Days

Specifications

1. 3D space inside of non-woven fibers, capture small particle directly, high efficiency, low cost, large capacity of dirty particles.

2. Low temperature resistance ( 80-120 °C)

3. Micron rating: 0.5-300um

4. Excellent resistant to hydrolysis, acids and alkalis.

5. Smooth surface, more defined pore size and good air permeability

6. Lower fiber release, Lower density, High mechanical characteristics

Polyester filter bag (PE filter bag)

| Breaking Strength-Warp | 1200 N / 5cm*20cm |

| Breaking Strength-Weft | 1400 N / 5cm*20cm |

| Breaking Elongation-Warp | 20% |

| Breaking Elongation-Weft | 30% |

| Continuous | 130 deg C |

| Surge | 160 deg C |

| Finish Treatment | Calendaring, Singeing, Heat setting |

| Anti-Acid | Middle |

| Anti-Abrasion | Excellent |

| Hydrolysis Stability | Middle |

| Anti-Alkali | Middle |

| Working pressure(Mpa) | 1.0 |

| Working temp℃ | -20-160 |

monofilament nylon filter bag (NMO filter bag)

Use the principle of surface filtration; non-deformable single fiber is made into mesh according to special weaving type, and is welded together to add mesh strength. The impurities can be hold back onto the filtering surface.

1. Single mesh-like structure

2. Fixed Grid

3. Good tensile - explosion proof performance

4. Strengthening the outer lining hem

5. Suitable rigid intercept impurities and high viscosity fluids

6. Easy to clean

7. Chemical resistance: base, aromatic hydrocarbons, aliphatic compounds

8. Surface filtration

Advantages: Monofilament structure can be repeatedly cleaned, it has lower consumption cost.

It suite the rough filtering cases where the filter fineness is low.

Micron rating: 1-1250um.normally:25-1000um.

| Type | Dia | length | Max flow M3/Hr | Filter area M2 | Volume (L) | ||

| inch | mm | inch | mm | ||||

| 1# | 7 | 177.8 | 17 | 431.8 | 20 | 0.25 | 8 |

| 2# | 7 | 177.8 | 32 | 812.8 | 40 | 0.50 | 17 |

| 3# | 4 | 101.6 | 9 | 228.6 | 6 | 0.09 | 1.3 |

| 4# | 4 | 101.6 | 15 | 355 | 12 | 0.16 | 2.5 |

| 5# | 6 | 152.4 | 20 | 508 | 18 | 0.20 | 3.8 |

Customized design bags to meet your specific application

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia

- Founded Year: 2012

- Address: 185 yuanke Rd

- Contact: zhu johnny