Metal Spinning

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Large Metal Spinning

Spinning in sheet metal belongs to the processing of local continuity, the instantaneous deformation zone is small, and the total deformation force is small. Some parts with complex shapes or

materials that are difficult to deform are difficult or even impossible to process with traditional techniques. They can be processed by spinning, such as pulleys, lamp accessories.

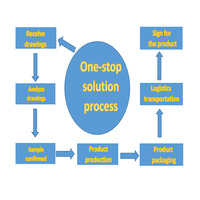

As one of the most professional metal spinning companies, ETCN cnc machining services supplier provides our clients with cnc metal spinning services, to make spinning in metal forming including

brass spinning, aluminium spinning, copper spinning, and stainless steel spinning, etc. Custom metal spinnings are also available.

Advantage of Metal Spinning

1. The tolerance of CNC metal spinning for beginners processing is very small and can reach about IT8, the surface roughness is less than 3.2, and the strength and hardness are significantly

improved.

2. The spinning processing material utilization rate is high, and the mold cost is less than one-fifth of the stamping mold. The economy of spinning molding is related to the production batch,

workpiece structure, equipment, and labor costs. Most processing uses spinning processing and stamping processing, shearing processing, ultrasonic cleaning, electroplating processing, and other

processes that are used in supporting applications to obtain the best economic benefits.

3. ETCN provides custom metal fabrication services, and various machinable materials like iron plate, aluminum plate, stainless steel, copper plate are available.

4. The shape that can be spinning can only be a rotating body, mainly barrel-shaped, conical-shaped, curved generatrix, and combined during spinning sheet metal forming.

Customized Metal Spinning Parts

If you want to know more types of manufacturing services, please visit our website.

There are many machining manufacturing companies in China, but we are one of the best choices for you.

- Country: China (Mainland)

- Address: Room 2310, No.39 South Chezhan Road, Hongkou District, Shanghai, China

- Contact: Ting Liang