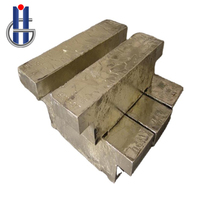

Tin ingot supplier

Product Quick Detail

- FOB Price

- USD $48,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard export package or as required.

- Delivery

- 3-15 days

Specifications

Product ingredients: Sn99.99

Working temperature: 265-275℃

Packing: net weight 25±1.5kg per ingot,

bundled with galvanized steel strips,

40 ingots per bundle, net weight 1000±30kg

Specifications: 400cmX100cmX100cm

Origin: China

Tin Ingot

(1) For the manufacture of tin-plated iron (tinplate);

(2) Used to make brazing solder;

(3) The electronic industry is used for tin plating on the surface of wires and electronic components and lead parts

(4) For the manufacture of tin bronze.

Tin is malleable and has good plasticity. Pure tin reacts slowly with weak organic acids and has good corrosion resistance. Even if it is corroded, the resulting compounds are generally non-toxic.

Therefore, a large number of tinplates are produced by hot-dip tinning, which are used in anti-corrosion or food industry. Tin-based bearing alloy (Babbitt) is an excellent wear-resistant material,

it has a low coefficient of friction and good toughness, thermal conductivity and corrosion resistance. Tin can also be configured into fusible alloys, solder, printed alloys, tin bronze, and tin

brass. Tin-containing zirconium-based alloys are used as nuclear fuel packaging materials in the atomic energy industry; tin-containing titanium-based alloys are used in aviation, shipbuilding,

atomic energy, chemical and nuclear medical equipment and other industrial sectors. Tin-niobium intermetallic compounds can be used as superconductors. The traditional Chinese medicine compounds of

tin are tin dioxide, tin tetrachloride and organic compounds of tin, which are respectively used as raw materials for ceramic glazes, coal dyes for printing and dyeing silk fabrics, as well as

insecticides, antifouling agents, wood preservatives and flame arresters.

- Contact: daisy fan