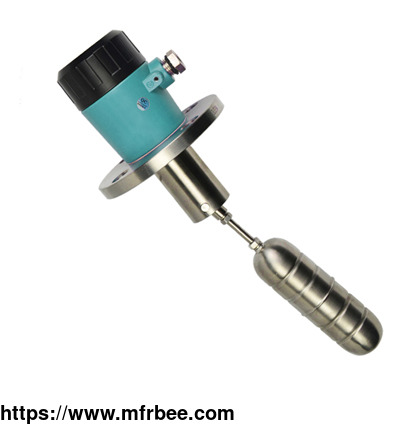

Side Mounted Level Switch

Product Quick Detail

- FOB Price

- USD $10.00 / Piece

- Minimum Order

- 5

- Place Of Origin

- Shanghai,China

- Packaging

- Carton box or as customer required

- Delivery

- 10-15 working days

Specifications

FEEJOY side top mounted level switch is a float type level switch, which is suitable for the control of the liquid level in the open or pressure container in the industrial process. When the liquid

level reaches the high and low limit, the electric shock relay can be used as a signal alarm device. It is a horizontal float level switch that uses the float to rise or fall with the liquid level

to about 20 degrees with the horizontal level when the float is subjected to liquid buoyancy. Our side mounted float level switch can be used in water treatment, petrochemical, shipbuilding and

other industries.

Specification of Side Mounted Float Level Switch

And we can manufacture according to customer's specification like:

Product Name stainless steel 304 float liquid level switch

Material SUS304 and SUS316

Color any of color

Protection Grade IP65

Float Material SUS304/SUS316L

Junction Box Al. alloy baking lacquer

Connection 2" JIS 5kg/cm2;customized

Installation Method horizontal installation

Application water, sewage, oil etc.

Suitable Gravity customized

Features of Side Mounted Float Level Switch

There are three specifications of ψ41, ψ50, ψ75 floats.

Plastic materials are PP and PVDF, which can be used in acid and alkali places.

SUS304 / 316 material, suitable for high temperature or high-pressure barrel tank.

Both side-mounted and top-mounted can be installed, the junction box protection level is IP-65.

The connecting flange has 92 x 92, JIS, DIN, and ANSI specifications; the mouth has 1-1 / 2, 2 "PT, BSP, or customer specified specifications.

Withstand pressure up to 50kg / cm², applicable specific gravity 0.25 ~ 0.65.

FEEJOY can supply OEM service for different float water sensor types among all industrial instrumentation suppliers, which include material, process connection, color, etc.

Working Principle of Side Mounted Float Level Switch

The side-mounted float level switch is based on the principle of liquid buoyancy. When the float moves up and down due to buoyancy, the reed switch in the junction box is affected by the magnet at

the arm end, which is used as the "NC" and "NO" exchange. The same principle is applied to the micro-level switch device. The magnet in front of the microswitch and the arms end magnet repel

each other and push the microswitch, causing "NC" and "NO" actions.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Founded Year: 2004

- Address: No.62, Lane 818, XiaNing Rd., Jinshan Industrial Park, Shanghai,China

- Contact: FEEJOY