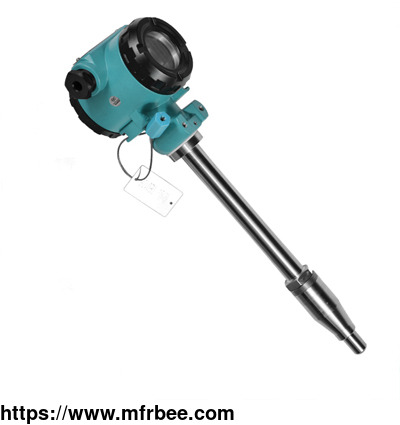

Temperature Instrument

Product Quick Detail

- FOB Price

- USD $10.00 / Piece

- Minimum Order

- 5

- Place Of Origin

- Shanghai,China

- Packaging

- Carton box or as customer required

- Delivery

- 10-15 working days

Specifications

Best Quality Temperature Transmitter Manufacturers

FEEJOY supplies different types of temperature instruments that convert thermal resistance, thermocouple, resistance and millivolt signals into a standard two-wire system 4 ... 20mA and transmits

the signal to the control room. Also named the thermocouple temperature transmitter, It is generally used in industrial sites. When the range of the traditional temperature transmitter needs to be

changed, it is generally adjusted by zeroing and adjusting two potentiometers, but these two potentiometers are the culprits that cause a large temperature drift of the product. Not only produce

products, but we also provide solutions to technical problems, even in the earliest stages of the project.

Development of Temperature Transmitter

With the advancement of science and technology, due to the tedious debugging of traditional analog temperature transmitters and poor comprehensive performance indicators, they can no longer meet

the needs of on-site users, nor can they meet the requirements of factory spare parts, nor can they meet the needs of temperature sensor manufacturers’ demand.

Therefore, the intelligent transmitter was born. One of them is to use CUP in the product, digitize the signal, and install special software on the PC during debugging, and use the data cable and

modem to change the range of the temperature transmitter. And the index number; the other is to embed the HART communication board in the intelligent product itself, and change the temperature

range and index number of the temperature transmitter through the HART protocol hand-held manipulator; there are two types of PA protocol and FF protocol respectively The temperature transmitter is

similar to the HART protocol. The application of HART, PA, and FF communication protocols is more convenient for product programming (no limit location), but it will increase the price of the

product itself and bring a burden to the owner.

Traditional differential temperature transmitter, PC programming temperature transmitters and HART programming temperature transmitters are the choices of most factories. However, after these

methods have been used on the site for many years, users often hear that the debugging is too cumbersome. It is impossible for every worker to be equipped with a PC, and even if there is a PC, it

may not be used because the debugging software of each manufacturer is not uniform and is cumbersome; Many factories are not equipped with HART Communicator, transmitters often need to adjust the

range is not very convenient. So is there a product that can change this situation? There are more differential temperature transmitter for customers to choose.

If you want to know more details of pressure temperature flow and level measurement instrumentation, please visit our website.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Founded Year: 2004

- Address: No.62, Lane 818, XiaNing Rd., Jinshan Industrial Park, Shanghai,China

- Contact: FEEJOY