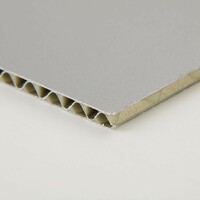

Copper Composite Panel

Specifications

| Mechanical Property | |||

| No. | Test Item | Test method | result |

| 1 | Density | ASTM D792-08 Method B | 1.804g/cm³ |

| 2 | Tensile strength | ASTM D638-10 | 31.3MPa |

| 3 | Flexural strength | ASTM D790-10 Procedure A | 86.1MPa |

| 4 | Flexural modulus | ASTM D790-10 Procedure A | 12100MPa |

| 5 | Shear strength | ASTM D732-10 | 22.3MPa |

| 6 | Shear resistance | ASTM D732-10 | 7090N |

| 7 | 180°Peel strength | ASTM D903-98 | 0.95kgf/mm |

| 8 | Peel torque | ASTM D1781-98 | 29.1mm.kgf/mm |

| 9 | Heat deflection temperature | ASTM D648-07 Method B | 94.2 ℃ |

| 10 | Coefficient of linear thermal expansion | ASTM D969-08 | 236.5*10-6 |

| *Test is based on 0.3mm red copper skin 4mm composite panel. | |||

| Notes: | |||

| ALUBANG copper is easily oxidized, clear protective film is suggested in case of adhesive residue | |||

| Please wear gloves during fabrication and installation of ALUBANG copper composite panel in case of finger print. |

- Country: China (Mainland)

- Founded Year: 2007

- Contact: Jialu bang