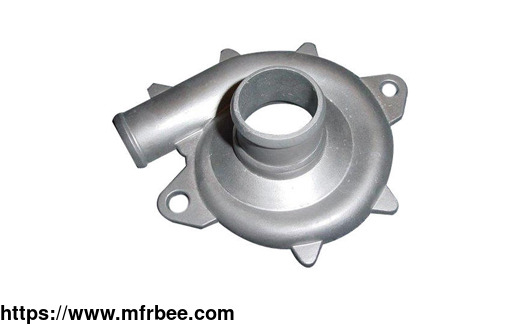

Low Pressure Die Casting

Specifications

The low pressure die casting is to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting part with the pressure as well. The pressure is

powered by the inert gas or compressed air inside the sealed crucible, pressure push the upper surface of the liquid metal, force the liquid flow through the lift tube and gating, fill into the

casting mold. The pressure is about 20~60 kPa. After full solidification, de-pressure the gas, make the unsolidified metal by gravity going back to crucible. The final casting part can be fetched

when the mold is opened.

Rayforce Manufacture is a private foundry supplier, we provide metal casting china, vacuum die casting, pressure die casting process pdf, low pressure die casting process pdf, low pressure casting

machine, low pressure die casting vs high pressure die casting and etc. Want to know types of pressure die casting or low pressure die casting advantages? Please contact us.

There are many pressure die casting manufacturers, but we are one of the best choices for you.

- Country: China (Mainland)

- Address: No.1-101, building no.18, gate no.189, Nanneihuan street, Yinze district, Taiyuan city, Shanxi province, China

- Contact: rayforce com