Precision Mould

Product Quick Detail

- FOB Price

- USD $5,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Shenzhen

- Packaging

- PALLET

- Delivery

- 4 weeks

Specifications

Injection Plastic Mold

Injection plastic mold is another name for plastic injection mold. This is just how people in various places call injection molds differently. The injection plastic mold can be made as single

cavity plastic mold or multi cavities injection mold according to the annual demand.

Injection Molding Mold Plastic Mold Maker Plastic Mold Making for Complex Parts Injection Mold Tooling

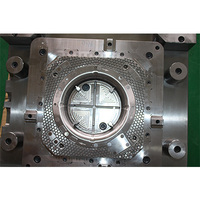

Gear Mold

Custom Plastic Gear Injection Mold Making, with many different dimensions and material, 2 cavities or 4 cavities customized plastic gear mould.

Customs Plastic Gear 49952 Gear Mold 492071 Motor Gear Mold 4995b Plastic Gear 4995d Plastic Gear Manufacturing 4995c Plastic Gear Mould 49122

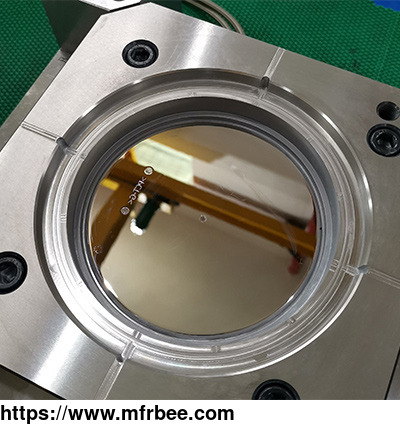

High Gloss Mould

HASCO standard transparent High Polish Injection Mould for customer coffee grinder hopper and cover. It is transparent PCTG plastic resin which is food grade, very critical for appearance

finishing...

High Gloss Plastic Mould 49445 High Gloss Polish Mould 49244 High Glossy Mold Tooling 49244

High Precision Mould

Plastic Injection Mold Maker 1253 Plastic Injection Mold for Plastic Molding Parts Plastic Fitting Mould 13966 Plastic Knob Mold Maker China 13966 Glass fiber Mold Making 13959 PA6 Mould

Manufacturing 13958

POM Mould

POM Mold 491315 POM Injection Mold 49171

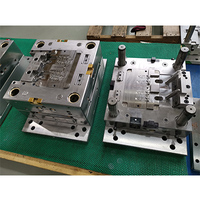

Family Mould

Family mould help to molding different plastic parts in the same mould, this solution saves tooling and molding cost.For most family mould, the plastic part is in same material & similar size...

Family Mold 49281 Family Mold Tool 491137 Family Injection Mold 491138

ABS Mold

ABS full name Acrylonitril Butadiene Styrene copolymer, with excellent comprehensive physical and mechanical properties, excellent low temperature impact resistance. Dimensional stability.

Electrical ...

ABS Plastic Mould 49180a ABS Injection Mold 49204a ABS Plastic Injection Mold 49443

How to build a plastic precision mould?

We have been manufacturing plastic precision mould parts for more than ten years. With our expertise and experience, we provide valuable mold opening suggestions to our customers according to their

specific needs, thus helping customers save manpower and resources.

Plastic precision mold components are normally required to be short mold cycle time and long life cycle, a good toolmaker should find the best mould solution combine the specific needs of

customers, the mould must be easy handling and maintenance.

In order to ensure the smooth progress of the high precision mold making project, detailed mould design analysis(DFM) must be done, and if necessary, mold flow analysis is required.

Before starting the processing, we need to communicate with the clients repeatedly, fully understand the needs of the customers, design the molds that meet the production requirements. DFM, mold

design must be confirmed by customers before starting to manufacture the moulds.

Stable employees are also very important. We have a comfortable working environment: central air conditioning, dehumidification system, exhaust system and epoxy floor. Our employees and technicians

have been working here for many years and this is an important factor in ensuring quality stability.

High Precision mould trial: With a special mold trial injection moulding machine, qualified mold trial operator to ensure professional and on-time sampling service for customers.

In HanKing Mould, we have a complete set of high-precision measurement equipment, capable of providing full dimension FAI measurement reports.

Weekly work schedules, mould pictures, and test reports will be sent to the customers.

With reliable quality, on-time delivery and reasonable price, not only provide professional one-stop service from plastic precision mould development but also flexible service to individual molds

or small batch plastic parts production. Whether the order is big or low volume, HanKing will make the best, all customers are VIP.

If you want to know more about mould manufacturing china, please visit our website.

- Country: China (Mainland)

- Founded Year: 2011

- Address: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen. China.

- Contact: Yoyo Tang