Weld Neck Flanges

Specifications

Product description

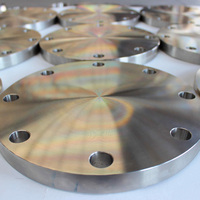

WELDING NECK RISE FACE FLANGE(WNRF)

Stainless steel weld neck flange are popularly used in excessive stress applications, with their capability to provide assisting power along with stress distribution. Weld neck flanges are

circumferentially welded at the neck where the integrity of the butt welded location can be without problems examined by means of radiography. The bores of both pipe and flange match, which reduces

turbulence and erosion inner the pipeline. The weld neck is consequently durable in fundamental applications.

Welding Neck Raised Face Weld Neck Flange Feature

Corrosion resistance

Pressure resistance

Tension resistance

Long service life and easy installation

Welding Neck Raise Face Flange (Wnrf)Forming:

Forged

Welding Neck Raise Face Flange Material

Stainless Steel:

OCr18Ni9, 0Cr18Ni9Ti, 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti, 00Cr19Ni10, 00Cr17Ni14Mo2, ASTM A182-F304, F304L, F304H, F316, F316L, F321, F321H, F347H

Super Stainless Steel:

ASTM A182-904L, 317, 317L

Duplex Steel:

ASTM A182-F51, F53, F44

Special Steel:

N06600, N08800, N08811

Alloy Steel:

16Mn, 12CrMo, 15Cr5Mo, Cr5Mo, 12Cr1MoV, ASTM A182-F11, F22, F91 F9 F5

Pipe Line:

ASTM A694-F42, F46, F48, F50, F52, F56, F60, F65, F70, F80

Carbon Steel:

ASTM A350-LF2, LF3 Q235A, 20#, ASTM A105

Welding Neck Raise Face Flange Standard &Size $ Rate

DIN2631 DN10-DN200 PN6

DIN2632 DN10-DN200 PN10

DIN2633 DN10-DN200 PN16

DIN2634 DN10-DN100 PN25

DIN2635 DN10-DN600 PN40

DIN2636 DN10-DN400 PN64

DIN2637 DN10-DN350 PN100

DIN2638 DN10-DN300 PN160

DIN2627 DN10-DN200 PN400

DIN2628 DN10-DN250 PN250

DIN2629 DN10-DN250 PN320

ASME/ANSI B16.5 1/2"-24" 150LB 300LB 600LB 900L 1500LB

1/2"-12" 2500LB

ASME B16.47 Serie A/B 26"-60" 150LB 300LB 600LB

26"-48" 900LB

Welding Neck Raise Face Flange Tests and Inspections

Analytic instrument of C&S

Machine Performance Test

Chemical Composition Analysis

Permeation Test

Ultrasonic Test

Metallographic microscope Test

Intergranular Corrosion Test

Hardness Test

Flattening Test

Ferrite test

Impact Test(Low temperature, Normal temperature,-196 temperature.)

Test methods for pitting corrosion resistance

X-ray flaw detection

Magnetic particle inspection

Welding Neck Raise Face Flange Documentation Offered

Raw Material Test Report

EN10204 3.1 Test Certificate

Heat Treatment Chart

Heat Treatment Report

Quality Assurance Plan

Inspection and Test Procedure Report

Welding Neck Raise Face Flange Application

Stainless steel welding neck raise face flange uses in oil and gas pipeline

Weld neck raise face flange uses in chemical industry

Alloy steel WNRF flange uses in plumbing

Weld neck flange uses in water supply systems

Asme b16.5 weld neck flange uses in power plant

Nickel alloy weld neck flange uses in paper industry

Monel 400 weld neck flange uses in general purpose applications

Monel 800 weld neck flange uses in fabrication industry

254Mo weld neck flange uses in petroleum

C-276 weld neck flange uses in papermaking

Alloy 20 weld neck flange uses in shipbuilding

High quality weld neck flange uses in petrochemical

Dulex steel weld neck flange uses in natural gas industry

Super duplex steel weld neck flange uses in ocean engineering

Ss Weld neck raise face flange uses in nuclear industry

Hastelloy raise face flange uses in food and beverage

Raise face flange uses in electrical powerplant

Ss nickel alloy weld neck flange uses in pharmacy

We are manufacturer, exporter, supplier, and trader of weld neck raise face flange for stainless steel, duplex steel, monel steel, hastelloy steel, super duplex steel, and carbon steel.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Middle East,Asia

- Founded Year: 2009

- Address: Central Industrial Zone Longwan District Wenzhou City,Zhejiang Province China

- Contact: Lucy Zhang