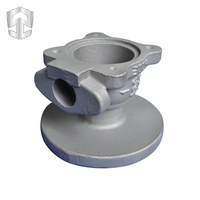

Carbon steel casting

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard export package or as required.

- Delivery

- 15 Days

Specifications

Carbon steel casting

Category:Steel casting

Carbon steel casting has high strength, plasticity and toughness. Common grades include Q195, Q215, Q235, Q255, Q275, etc.

Product Description

Carbon steel casting is used in heavy machinery to manufacture parts that are subject to heavy loads, such as rolling mill stands, hydraulic press bases, etc. It is also used to manufacture more

important mechanical parts with complex shapes and high requirements on mechanical properties, and it is difficult to form by forging and other methods in the process.

Carbon steel refers to iron-carbon alloys, generally the carbon content is between 0.0218% and 2.11%. As the carbon content is higher, the strength of carbon steel is higher, but correspondingly,

the plasticity of the product will decrease. Usually there are elements such as silicon manganese in carbon steel. These different types of small amounts of elements will have different effects on

the strength and hardness of carbon steel products.

Cast carbon steel generally has a relatively low production cost, gradually has high strength and toughness, and has good plasticity, and can be used to manufacture parts that bear large loads,

such as rolling mill stands for heavy mechanical clocks, hydraulic press bases, etc. It can also be used to manufacture parts that are subjected to high forces and shocks, such as wheels, couplers,

bolsters and side frames on railway vehicles.

- Country: China (Mainland)

- Market: Americas,Europe,European Union

- Founded Year: 2021

- Address: Jiulong Street Industrial Park, Jiaozhou City, Qingdao, Shandong Province, China

- Contact: Daizy Fan