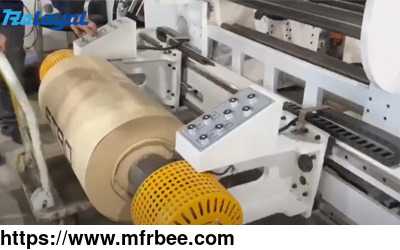

High-Speed Slitting Rewinder

Product Quick Detail

- FOB Price

- USD $5,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

China high speed slitting machine are a high speed, high precision equipments. High precision slitting machine are ideal for the high demand production of label sticker, flexible packaging

materials, electronic protective film well as medical material. By adding PLC on the standard High precision slitting machine, the whole machine operation can be controlled via human-machine

interface and all the tension can be added and subtracted automatically.SIEMENS PLC program ensures automatic control and easy operation, friction shaft makes rewinding effect excellent, servo

driven mechanism keeps machine running in high precision, automatic pushing and unloading can save your exchange time, automatic blade can be set as a option.High speed precision slitting line is

suitable for electric and optical industry. Beside the standard types of high speed slitting machines, we also provide customized slitting unit design in this serial to accomplish various

industries.

We help our clients improve their supply chain by providing good quality tape slitting machine for sale with the most competitve slitter machine price. Contact us now for your next high speed

precision slitting line project. We guarantee you will be impressed.

Raloyal, your loyal high speed slitting machine supplier partner.

There are three categories of high speed slitter for sale: standard high speed slitting machine, standard high speed slitting machine with slip shaft, and standard high speed slitting machine with

slip shaft and shaftless unwinding chuck. Standard high speed slitting machine plus PLC can reach the high speed of 200m/min. There are also three sizes of high speed roll slitting machine for sale

can be chosen to meet all kinds of width of raw materials. They are 1300mm, 1700mm, 2000mm. Standard high speed slitting machines are ideal for mass production of tape, packaging, printing, paper,

etc.

If you want to uplift the precision of material slitting and rewinding, the standard high speed slitting machine with slip shaft is very suitable and highly recommended. Slip shaft can achieve the

perfect fixing for different kinds of materials rewinding, and can reduce the cost waste occurred at the same time. This high speed paper roll converting equipment is controlled by two servo

motors, which control the unwinding and 2 slip shafts rewinding, making the tension be controlled much better and rewinding more smoothly and slitting more accurately.

Standard high speed slitting machine with slip shaft and shaftless unwinding chuck is ideal for large-diameter heavy rolls and can solve the problem of tube deformation. And the speed of this high

speed roll converting equipment is 300m/min. It is an ideal slitting machine for demanding production at high speed and high precision.

How Does High Precision Slitting Machine Works?

Slitting is a converting process cutting wide mother material rolls to narrow ones. In rewind slitting process, the material roll will be fed into the unwind section, slit in the slitting section

and rewind on one or more shafts to form narrower rolls. For the high speed roll converting equipment that can rewind slit, we call it a slitting machine, a slitter or a slitter rewinder.

High speed slitting and rewinding machine can be divided into three sections: unwind section, slitting section and rewinding section. High speed slitting machine is widely used for slitting soft

materials such as adhesive labels, plastic films, paper and non-woven and also hard material like metal, copper foil and aluminum foil. The slitting part has some options suh as razor slitting,

rotary shear slitting, crush cut slitting and hot knife slitting. Razor slitting is very simple to set and low price, but it needs to be changed frequently. This is widely used on thin plastic

films. As to Rotary shear slitting, as its names suggest, the slitting provides a scissor cutting effect. It works well with slitting foils, paper and plastic films. As to crush cut slitting, it an

ideal for slitting non-wovens and foams. Hot knife slitting applies to a heated blade to cut through an anvil.

Slittter Machine Parts And Their Functions

Automatic Loading: Automatic loading by cylinder

Splicing Table: Friendly operating and increase productivity.

Automatic Length Counter: count the length automatically

Slitting Knife: Self-lock type knife, shorten set-up time and protect the knife shaft.Safety cover for slitting section to ensure safty.

Friction Shaft: Separated tension automatic adjustment. Double beads type friction shaft, with high precision.

Ruian Loyal Machinery Co, Ltd., is a professional high speed slitting machine manufacturer, we provide slitting machine process, slitting machine china, vertical slitting machine, foam slitting

machine and etc. Contact us to know slitting machine meaning and slitting machine operation.

There are many high speed slitting line manufacturers, but we are one of the best choices for you.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas,Europe,Asia,Middle East

- Founded Year: 2009

- Address: No 88,jinyuan Road,Dongshan Economic Development Zone,Ruian city Zhejiang province,China

- Contact: lyslitter