Timber Formwork

Specifications

TECON concrete formwork timber mainly includes BASE 20 Wall Formwork, Flex 20 Slab Formwork, Slab Table Formwork and BASE 20 Column Formwork.

Combining different components such as film faced plywood, steel waler, and steel prop, all above shuttering timber for concrete formwork can be assembled and used for wall, column, slab, and beam

casting.

Due to the large size design, the weight of each formwork unit is also relatively high. Thus crane assistance during site transportation is a must.

Types of Timber Formwork

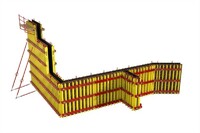

TECON BASE 20 Wall Formwork

TECON BASE 20 is a universal wall formwork consisted of H20 timber beam, TECON-Form plywood and steel waler and others. Those independent components can be freely assembled. Therefore, TECON BASE

20 formwork is dedicated to suiting all sizes and shapes of walls.

Features of BASE 20 Formwork

Feasible in column formwork solution.

Efficient on-site by pre-assembled big-size formwork panels under crane assistance.

Quickly achieve fair-faced concrete finishing by high-quality shuttering, few tie rods and joints.

Suitable for all size and shape requirements due to flexible arrangements of girders and walers.

Specifications of BASE 20 Formwork

1. Flexible panel widths are determined by the length of the steel waler.

2. It consisted of H20 timber beam, steel waler, TECON-Form Plywood and other accessories.

3. Flexible panel heights are determined by the H20 girder and panel strut length, up to 8m. "3.0m*3.0/3.6/4.0/6.0m;

4.0m*3.0/3.6/4.0/6.0m;

5.0m*3.0/3.6/4.0/6.0m;

6.0m*3.0/3.6/4.0/6.0m;"

4. Customized irregular shapes are determined by shaping wood and special shape steel waler.

5. Adapt to various fresh concrete pressure up to 90kN/sqm by the flexible arrangement of girder and walers.

Application of BASE 20 Formwork

Residential & commercial buildings, concrete tanks, basement, bridge abutment and piers, columns, or irregular concrete structures shape wood and others.

Slab Flex 20 Formwork

TECON Slab Flex 20 formwork is the most flexible slab formwork. It's highly optimized for multiple beams. Slab Flex 20 is mainly consisted of H20 timber beam, shoring props and TECON-Form plywood.

Their position and spacing can be freely connected. Thus flex system formwork provides maximum flexibility and an ideal solution for most complicated plans, slabs with drop beams or forming

operations in narrow spaces.

Features of Slab Flex 20 Formwork

Efficient assembly by manual.

Easy transportation and storage.

Flexible and ideal for all ground plans.

Long service life with systematic components.

For all finishing requirements by the different quality of shutters.

Specification of Slab Flex 20 Formwork

For any slab plan and slab height.

For different slab thicknesses up to 100cm.

No infill areas due to specifically tailored planning.

Beam 20 Bracket and Beam 20 Extension with easy tighten system by D15 rod & nut.

The main beam & secondary H20 timber beam, and TECON-Form Plywood at 18mm or 21mm.

TEP-B series prop and heavy-duty prop TEP-D, TEP-E with high workload-bearing capacity for your choice.

Application of Slab Table Formwork

Residential & commercial buildings, and factories with large area and multiple floors etc..

Related products of Slab Table Formwork

BASE 20 wall formwork, Slab flex 20 formwork, Aluflex formwork

As one of scaffolding manufacturers in china, we have types of related products for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Founded Year: 2013.11.13

- Address: Room1105-1110, Block A, Building 2, LEFO Commercial Center, Wuzhong District, Suzhou, Jiangsu Province, China

- Contact: Edgar Chow