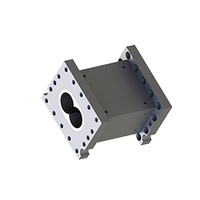

Extruder Closed Screw Barrel

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Place Of Origin

- China

- Minimum Order

- 2

- Packaging

- N/A

- Delivery

- 30 Days

Specifications

There are two main types of extruder closed screw barrels, 4D and 6D, with 4D being the most. According to the different selection of the materials from the customers, the corresponding bushing

materials can be selected to meet the needs of the modified customer.

Technical Data of Extruder Closed Screw Barrel

Brand:LESUN, the screw and barrel manufacturer

Model:φ20 mm ~φ300 mm

Material:38CrMoALA / W6Mo5Cr4V2 / HIP

Properties: Wear-resisting, Corrode-resisting, Durable

Application: Extruder

The Selection Of The Extruder Closed Screw Barrel Material:

Integral closed machine barrel, Nitrided steel, quenched and tempered, gas nitrided after processing;The sleeves of the bimetal bushing barrel can be divided into C-shaped sleeves and integral

sleeves, which are wear-resistant; nickel-based alloys are resistant to corrosion and wear. There is also a water-cooled circulation channel in the cylinder wall of the closed-end machine cylinder,

which is close to the ∞-shaped working cavity. It can achieve high-precision cylinder temperature control in conjunction with the casting electric heating tile (± 2 ℃)

If you want to know more types of screw barrel, please visit our website.

With regard to production specifications, LESUN not only offers standard twin screw extruder parts made by general screw and barrel manufacturer, but also provides special-purpose feed screw design

and manufacturing service according to your requirements. Meanwhile, we also provide surveying and mapping business as well as processing business for accessories made by major extruding machine

companies.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:

- Founded Year:2004

- Address:Zhang Qiao Industrial Zone Lu Kou street, Jiang Ning District ,Nanjing city,211113,Jiangsu Province,China.

- Contact:lesun Screw

Other products from NANJING LESUN SCREW CO.,LTD

Relate products of Extruder Closed Screw Barrel

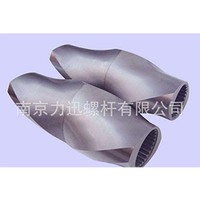

Twin-screw Feed Extruder

What is a Twin-screw Feed Extruder? The H series twin-screw feed extruder is primarily used for the production and processing of various floating, sinking, and slow-sinking aquatic feeds. It can meet various customer demands, including 0.6mm aperture floating and 0.8mm aperture ...

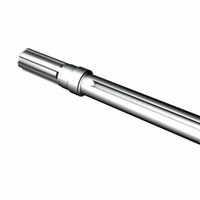

Flat twin screw barrel

Diameter range:from 60mm to 250mm L/D ratio:16-40 ...