Enzymes

Product Quick Detail

- FOB Price

- USD $8.00 / Piece

- Minimum Order

- 50

- Place Of Origin

- China

- Packaging

- bag

- Delivery

- 15 Days

Specifications

Enzymes are proteins that act as biological catalysts, which are non-toxic and environment-friendly. Enzyme products can create chemical reactions in the body and accelerate the reaction rate to

help support life.

Entering the 1980s, bioengineering has been developed rapidly in China as new technology. As a consequence, the manufacturing and application of enzyme engineering have gradually expanded to the

food industry. Against this background, Yiming established its first manufacturing plant in 1998 in Taixing city, Jiangsu Province. Nowadays, Yiming has developed transglutaminase fermented from

streptoverticillium mobaraense. As one of the professional industrial enzyme manufacturers in China, Yiming is the first Chinese company and the second company in the world after Ajinomoto to

realize the production of transglutaminase by microbial fermentation. With enzymes used in food processing becoming popular and we can provide you with different types of high-quality food enzymes.

Application Of Enzymes In Food Industry

Enzyme is an active protein. Its catalytic is more effective than inorganic catalysts.

1. Flour products with enzymes

Enzymes are extracted from living organisms and made through modern biotechnology. It is a pure natural biological product and green food additive. It plays a significant role in a variety of

special flour production and transformation.

2. Dairy processing with enzymes

The main enzymes used in dairy processing are catalase and lactase. Catalase has high enzymatic activity in bovine colostrum and is mainly used to remove excess hydrogen peroxide in dairy products,

thereby killing pathogens by using H2O2.

3. Meat processing with enzymes

Enzymes used in the meat industry are mainly used to improve product quality (color, smell, taste, etc.) and increase the added value of by-products.

4. Beverage processing with enzymes

The main enzymes used in this field are pectin, cellulase and amylase. These enzymes are mainly used for peeling fruits, clarifying juice, reducing juice viscosity, improving juice utilization

rate, enhancing stability, and also for making vegetable juice, extending the shelf life of fruits and vegetables, reducing nutrient loss, etc.

Advantages of Using Enzymes in Industrial Manufacturing Processes

1. Sustainable Solutions

Enzymes enable all walks of life to ensure the quality and stability of their products by improving production efficiency. By reducing the use of energy, water and raw materials and generation of

less waste, they also help provide consumers with eco-friendly products.

Most industries are faced with production waste that is harmful to nature. This is not the case with enzymes, because they are completely biodegradable. After industrial enzymes complete their

work, they are broken down into amino acids that are naturally recovered in the environment. Enzymes also help improve resource efficiency in the food chain by reducing processing losses.

2. Quality Improvement

Enzymes can meet the convenience requirements of modern society without affecting health and safety. Enzymes can make high-quality products, increase yields and avoid harmful by-products. For

example, in the fruit juice industry, enzymes make the fruit easier to squeeze and the juice is clearer. Finally, enzymes can also improve the health of food and help meet special dietary needs.

For example, they promote the production of low-salt processed meat or enable millions of lactose intolerant people to digest dairy products.

How Do Enzymes Work

An initial input of energy is required before the reaction takes place in all chemical reactions. If this initial energy requirement (called activation energy or energy barrier) is small, then the

reaction will happen quickly and easily. If the activation energy is large, the reaction will take longer. The role of enzymes is to reduce the activation energy required for chemical reactions to

occur.

First, the enzyme binds to the substrate and deforms its shape slightly. The change in shape activates the substrate molecule and reduces the total activation energy required to turn the substrate

into a product. As the number of activated substrate molecules increases, the conversion of substrate to product also increases.

FAQs of Enzymes

What is an enzyme tg?

In living organisms, the enzyme acts as a biological catalyst. It controls the rate at which chemical reactions proceed without themselves being altered in the process. Many of these reactions

would not take place at a perceptible rate without enzymes.

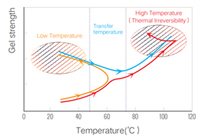

How temperature affects enzymes?

At low temperatures, the number of successful collisions between the enzyme and substrate may be reduced because their molecular movement decreases. The reaction is slow.

Higher temperatures can disrupt the shape of the active site, which may reduce the activity of natural enzymes, or even prevent enzymes from working. Under these circumstances, the enzymes may have

been denatured.

Are enzymes sensitive to pH?

Enzymes are sensitive to pH. Changing the pH of the surroundings may change the shape of the active site of an enzyme. For example, transglutaminase works best at 6.0pH to 7.0pH.

Are enzymes safe for everyone?

Most of the enzymes are extracted from microbial cultures. The refined enzymes will not contain bacteria, while the crude enzymes may contain small amount of microorganisms. Thus, the dosage of

using common enzymes should be strictly controlled, and it is best to use enzymes with food-grade purity.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 1998

- Address: No.333 Longhe Road, Taixing City, Jiangsu Province, China

- Contact: YIMING BIOTECH