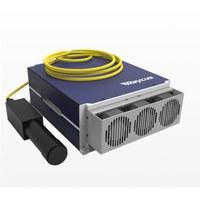

300W QCW Fiber Laser

Specifications

In the manufacturing process of the inner liner of the traditional washing machine, the inner tube riveting technology has been widely used. At present, most of the manufacturing technology of the

inner tube of fully automatic washing machines on the market adopts the "fastening" technology, but there will be gaps or unevenness in the joint of the inner tube, which causes the strength of

the tub to be low and unnecessary wear and tear on the clothes.

In order to further improve the reliability and refinement of the inner tube, washing machine manufacturers apply laser welding technology to the new products of uniform power washing machines,

avoiding the gap and unevenness of the inner tube, and comprehensively improving the reliability of the product while taking care of the clothes.

The 28th issue of Rayclass shows the new changes that laser welding applications bring to washing machine liner

Advantages of laser 300w welding

1) From the perspective of process analysis, the welded seam of the inner cylinder created by the seamless laser welding technology has a uniform structure, fewer pores and fewer defects. The

strength is nearly 4 times that of the inner cylinder using riveting technology, and the smoothness of the interface is increased by nearly 15 times. The smooth seam of the inner cylinder is

designed to better protect the fabric of the clothing, which is an experience that is difficult to achieve with riveting technology. In addition, due to the increased strength of the inner tube,

the maximum rotation speed of the uniform power washing machine during the dehydration process is also increased by 25% compared with the ordinary fully automatic washing machine. The dehydration

efficiency is greatly improved, and it consumes less power and time, and it is also satisfying the consumer's demand for quality life under the current consumption upgrade trend;

From the perspective of production efficiency, the laser seamless welding technology can make the inner cylinder welding spot small, narrow welding seam, neat and beautiful, without processing

after welding, and the production efficiency can be increased by 3 to 5 times.

We also have kinds of high quality china 1500w fiber laser for sale, anything you need, please contact us.

- Country: Afghanistan

- Address: No.999 Gaoxin Ave.East Lake Hi-Tech Devel. Zone, Wuhan, Hubei, P.R.China

- Contact: raycus laser