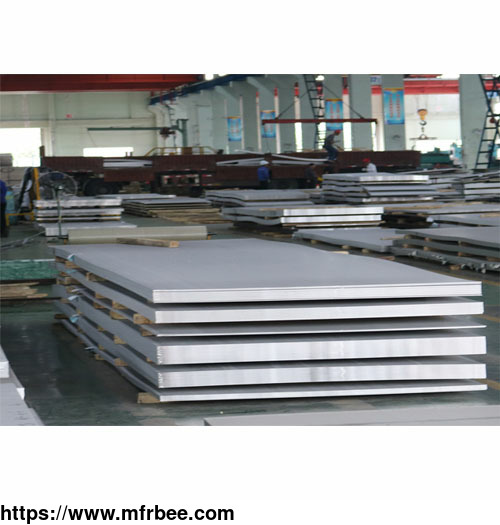

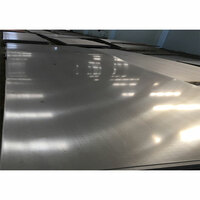

316L Stainless Steel Sheet Corrosion Resistance

Specifications

Chinese Standard (GB)-old grade: 00Cr17Ni14Mo2, new grade: 022Cr17Ni12Mo2, Japanese standard: SUS316L, American standard ASTM-316L, as a low-c series of 316 steel, in addition to the same

characteristics as 316 steel, and 316l stainless steel plate' s resistance to grain boundaries Excellent corrosiveness O316L steel is a product with special requirements for anti-grain boundary

corrosion. Because of the addition of Mo, its corrosion resistance, atmospheric corrosion resistance and high temperature strength are particularly good, and it can be used under harsh conditions;

316l stainless steel sheet has excellent work hardening (non-magnetic). Due to the addition of Mo, its corrosion resistance, atmospheric corrosion resistance and high temperature strength are

particularly good, and it can be used under harsh conditions; it has excellent work hardening properties and is non-magnetic. Shanxi Goldpro can provide 316l stainless steel in good price with high

quality performance.

What does the L stand for in 316L Stainless Steel Sheet?

The L in 316L stands for carbon content. 16L is a stainless steel material grade, AISI 316L is the corresponding American label, and sus 316L is the corresponding Japanese label. China's unified

digital code is S31603, the standard brand is 022Cr17Ni12Mo2 (new standard), and the old brand is 00Cr17Ni14Mo2, which indicates that it mainly contains Cr, Ni and Mo, and the number indicates the

approximate percentage.

L means ultra-low carbon, that is, the content of C is less than 0.03%. 316L composition range (%): C≤0.03,Si≤1.00,Mn≤2.00,P≤0.035,S≤0.03,Ni:12.0-15.0,Cr:16.0-18.0,Mo:2.0-3.0.

Processing Service Of Our 316l Stainless Steel Sheet

Cutting+Slitting - 316L stainless steel narrow strip,special length/width plate

(1) Flame cutting: The cost of flame cutting equipment is low and it is the only economical and effective means to cut thick metal plates, but it has its shortcomings in thin plate cutting.

(2) Laser cutting:Laser cutting equipment can cut stainless steel plates below 30mm. Adding oxygen to the laser beam can cut 40mm thick carbon steel, but after oxygen cutting, a thin oxide film

will be formed on the cutting surface.

Wire cutting: It is developed on the basis of EDM perforation and forming. It has not only

(3) developed the application of EDM, but also replaced EDM perforation and forming in some aspects.

(4) Shearing cutting:Uses a moving upper blade and a fixed lower blade and uses a reasonable blade gap to apply shearing force to metal plates of various thicknesses so that the plates can be

broken and separated according to the required size. Shearing machine is a kind of forging machinery, and its main function is the metal processing industry.

(5) Plasma cutting:It is a processing method that uses the heat of a high-temperature plasma arc to partially or partially melt (and evaporate) the metal at the incision of the workpiece and uses

the momentum of the high-speed plasma to remove the molten metal to form an incision.

(6) Slitting: Also known as slitting, refers to the process of uncoiling, slitting, leveling, and winding of stainless steel coils into coils of the required width.

Surface processing - 8K mirror, HL hairline, color coating

Bending+Welding - OEM customized products as drawing

As a professional stainless steel factory, we provide stainless steel china, steel 16 gauge, stainless steel gauge thickness, stainless steel flat stock and etc. For more information, please feel

free to contact us!

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia

- Founded Year: 2012

- Address: No. 2, Epang Road, Lianhu Dist,xian city,Shaanxi province, China

- Contact: Goldpro .com