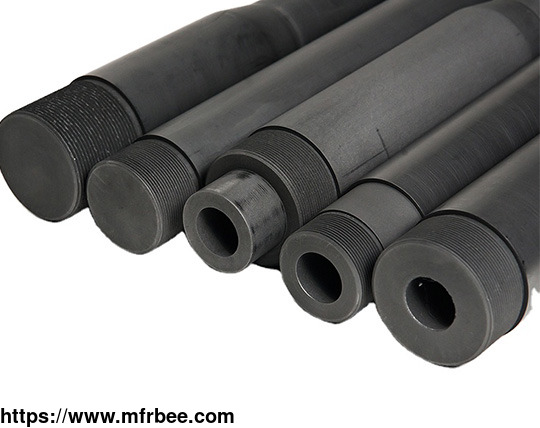

GRAPHITE ROD ELECTRODE

Product Quick Detail

- FOB Price

- USD $20.00 / Piece

- Place Of Origin

- China

- Minimum Order

- 25000

- Packaging

- Standard fumigation-free wooden cases

- Delivery

- 15 Days

Specifications

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:

- Founded Year:2018

- Address:Industrial Agglomeration Zone of Baofeng County, Pingdingshan City, Henan Province, China

- Contact:whgraphitesupplier com

Other products from Pingdingshan Wanhui Graphite Co., LTD

Relate products of GRAPHITE ROD ELECTRODE

WH conductive graphite rod uses graphite block as raw material. After the processing of professional lathe equipment, it is made of different diameters and lengths. The graphite rod current graphite rod current density is a very important parameter, and you can contact us for ...

Definition of Huaro Graphite Electrode Graphite electrode is high temperature resistant graphite conductive material. It is made of petroleum coke and pitch coke as aggregate and coal tar pitch as binder. The production process for graphite electrode includes Calcining, ...

According to the classification of electric furnace steelmaking power level and the difference of raw materials used for producing Graphite electrodes as well as the physical and chemical indexes of finished product, graphite electrodes are divided into three types: regular ...