Underwater Curing Epoxy Coating

- Packaging

- N/A

- Delivery

- N/A

Specifications

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:

- Founded Year:1994

- Address:Jingbao Industrial Zone, South Of Jinbao Expressway,Beicang Town, Beichen District,Tianjin,China

- Contact:Paintinchina com

Other products from Tianjin Jinhai Special Coatings & Decoration Co., Ltd

Relate products of Underwater Curing Epoxy Coating

Underwater Curing Epoxy Coating Underwater paint are two-component, formulated with special resins, extender pigments, fillers and curing agents. Its biggest feature is that it can continue to cure underwater to form a strong, high-strength paint film. It is mainly used for ...

Product Category: neodymium block magnets/neodymium rectangular magnets/ neodymium magnets blocks Product Name: epoxy coated magnets Available Grade: N35-N52, 33M-50M, 35H-48H,35SH-45SH,28UH-40UH,28EH-38EH,28AH-33AH Surface Treatment: NiCuNi, Zn, NiCu+Sn, NiCu+Ag, ...

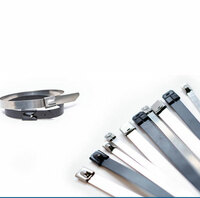

The pvc coated zip ties usually use 201 304 stainless steel as the main material and are often coated with a PVC cover. The coated stainless steel cable tie product will be insulated from acids, alkalis, salts, and oxidation. As a result, our PVC and nylon coated stainless ...