Fiber Bragg Grating (FBG)

Product Quick Detail

- Place Of Origin

- China

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 10

- Packaging

- N/A

- Delivery

- 21 Days

Specifications

Fiber Bragg Grating (FBG) is a basic element widely used in telecommunication, laser and sensor fields. With superior apodized technologies, AtGrating can provide high quality FBGs to meet the

requirements of different customers.

Types of Fiber Bragg Grating (FBG)

Apodized FBG

FBG china is a diffraction grating formed by periodically modulating the refractive index of the fiber core by a certain method. It is a passive filter element, and has been widely used in the

production of fiber lasers, fiber optic communications and sensing.

High Temperature FBG

Standard High Temperature FBG is inscribed in a Polyimide coated SMF-28 fiber, and can withstand high temperature up to -40 ~ 300 ℃, this kind of FBG is wildly used in Oil & Gas, Aerospace

industries.

FBG Wavelength Locker

Also know as FBG Wavelength Stabilizer, it is used for external cavity of pump Laser Diode, we can cover wavelength of 980nm, 1064nm, 1480nm or 1550nm, the components are wildly used in fields of

DWDM, FDM, spectral testing, fiber laser and optical amplifier.

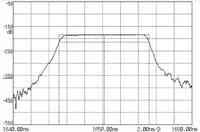

Chirped FBG

It refers to a kind of fiber grating in which the core refractive index change amplitude or the refractive index change period of the fiber gradually becomes larger (smaller) along the axis of the

fiber. With its character of a wide reflection spectrum, Chirped FBG can be used as a dispersion compensator.

Long Period Fiber Grating

LPG can reflect light of a certain wavelength in the incident light, and the reflection bandwidth is narrow. In the field of sensors, LPG can be used to make temperature sensors, strain sensors and

other sensors; in the field of optical communication, LPG can be used to make bandpass filters, add-drop multiplexers, and demultiplexing of WDM devices, etc.

Phase Shifted FBG

With its characteristics of high quality wavelength selectivity, low insertion loss and polarization independent, high reliability, Ultra-narrow transmission peak, Phase Shifted FBG is mainly used

in the production of low-noise single-frequency narrow-linewidth fiber lasers, narrow-linewidth single-frequency semiconductor external cavity lasers and other fields.

Tilted FBG

Tilt fiber Bragg grating (also known as blazed fiber Bragg grating) is a new type of passive optical device in which the grating plane forms a certain angle with the fiber axis. Due to its own

structural characteristics, TFBG is mainly used on the research of sensing.

Athermal Packaged FBG

A method for compensating the temperature coefficient of fiber gratings by using a packaging sleeve with a negative temperature coefficient. The special packaging results in good temperature

characteristics, small in size, light in weight and strong in impact resistance, is an ideal packaging method for fiber grating.

Femtosecond FBG

Femtosecond FBG is a new technology that directly writes Fiber Bragg Gratings through fiber coating. It can not only maintain the original strength of the fiber, but also increase the

characteristics of high temperature resistance and flexible configuration.

Gold Coated FBG

Gold coated FBG is the FBG which is recoated with a certain area of gold, so as to protect the FBG. To save the cost, we do not need to gold coated the pigtails, only the sensing element is

recoated with gold, hence, the FBG has the ability to resist the high temperature upto 1,000°C.

Polarization Maintaining FBG

Polarization Maintaining FBG is widely used in various fields of the national economy such as aerospace, aviation, marine manufacturing technology and communication.

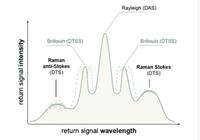

Fiber Bragg Grating (FBG) Working Principles

Fiber Bragg Gratings are made by laterally exposing the core of a single-mode fiber to a periodic pattern of intense laser light. ... All the reflected light signals combine coherently to one large

reflection at a particular wavelength when the grating period is approximately half the input light's wavelength. Those are the general fiber bragg grating sensor working principle.

Fiber Bragg Grating Technology Fundamentals and Overview

Fiber Bragg Gratings are a type of reflective structure constructed in a part of an optical fiber with a periodic variation in the refractive index of the fiber core along the longitudinal

direction of the fiber. When light passes through the FBG, only the light of a particular wavelength is reflected. Spectrum center wavelength of reflected light is called Bragg’s wavelength.

When a broadband light beam is sent to an FBG, induced reflections of certain wavelengths of the coupled light occur at the points with the manipulated refractive index.

When the FBG is subject to external mechanical stress, the spectrum of the reflected wavelength range shifts, meaning that the mechanical stress on the fiber can be measured and interpreted.

FAQs of Fiber Bragg Grating (FBG)

Q

Can we put different sensor types on the same fibre?

A

Yes, AtGrating's FBG products allow the user to combine different sensors types, e.g. temperature, strain and vibration all on a single fibre.

Q

How reliable are FBG sensors?

A

Optical fibre fatigue reliability is very high and FBG sensors benefit from this fact. For instance, client tests found that AtGrating's FBG sensors were still 100 % functional after 6 x107 cycles

of tensile and compressive fatigue loading.

As a fbg company, we can offer kinds of related products for sale, and the fiber bragg grating price is affordable anything you need, please contact us.

AtGrating is a professional supplier for optical fiber sensing. AtGrating offers industrial solutions by providing customized sensors and sensing instruments that add value, reduce uncertainty, and

maximize performance from our customer systems.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Founded Year: 2010

- Address: 5F, Building B, Chiwan Industry Park, Shaodi Road, Shekou, Nanshan, Shenzhen City

- Contact: at grating