Casting

Specifications

Casting is one of the basic processes of modern equipment manufacturing. The casting process can be divided into three basic steps, namely casting metal preparation, mold preparation, and sand

casting and die casting processing. Casting metal refers to the metal material used for casting services in the production of castings. It is an alloy in which metal elements are the main

components and other metals or non-metal elements are added. It is usually called casting alloy, which mainly includes cast iron, cast steel, and cast non-ferrous alloy.

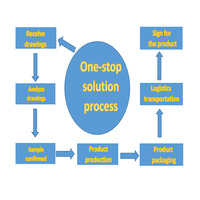

As one of the professional titanium casting companies, ECTN provides our clients with advanced metal vacuum pressure casting services such as high pressure aluminum casting and low pressure

aluminum casting, custom aluminum casting, custom brass casting, permanent mold aluminum casting and etc.

As a common catrgory of advanced metal casting, gravity mold casting is an ideal choice for the production of various complex aluminum castings of automotive parts.

Casting FAQs

Casting Cracks

1. Usually, the metal solidifies too fast at this place, resulting in casting defects (joints);

2. Cracks caused by high temperatures.

The solution: Use low-strength investment materials, reduce the casting temperature of the metal as much as possible, and do not use alloys with low ductility and brittleness.

Easy To Crack When Die-casting Thin-walled Products

Metal Splashing During Die Casting

Why Can't The Inner Processing Of Aluminum Die-casting Hole Exceed 0.25mm

Unclear Marking During Casting

If you want to know more about aluminium casting price, please contact us.

As a cnc company, we will do our best to meet all the needs of customers.

- Country: China (Mainland)

- Address: Room 2310, No.39 South Chezhan Road, Hongkou District, Shanghai, China

- Contact: Ting Liang