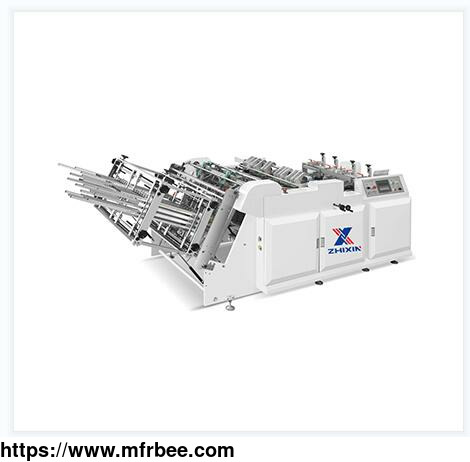

Double Workshop Carton Forming Machine

Specifications

Double Workshop Carton Erecting Machine is an automatic machine, specialized in making food cartons, boxes, containers which are made from cardboard, paper, paperboard, corrugated paper etc.

The food box (carton, container, dish, tray) is widely used as a burger box, hot-dog box (tray), one block box, food pail box (Chinese food box, takeaway box), fries box (chips box, chips tray),

lunch box, meal box, etc.

Features of Double Folding Machine

Press Mold

Servo motor controls the forming mould. (press mould) (advanced, more accurate than mechanism cam control)

Using Full Servo System

Using full servo system (3 servos in machine replace cam system)

Easy Exchange

Easy exchange moulds to make different products, charging and adjusting time is very short.

PLC Program

PLC program controls the whole line, available to make complicated boxes.

Automatic Collection, Stocking, And Counting

Automatic collection, stocking, and counting.

Easy And Safe

Man-designed to control buttons and panels, more easy and safe runs by user.

Save Time

PLC could save the adjusted parameter after you finish the adjustment, it will help you save time.

Specification of Double Workshop Carton Forming Machine

model : ZX-1600

speed: 100-320pcs/min

Material: 200-620gsm

Corrugating paper thick:1.6mm

box size: Length: L100-450mm

Degree:5°-45°

Width: B100-600mm

Height: H 15-200mm

Power : 6kw

Air requirement: 0.5Mpa, 0.4cube/min

Voltage: 380V 50Hz

size: 3600*1850*1700mm

weight: 2800kgs

If you want to know more types of horizontal cartoner, please visit our website.

As a reliable packaging machinery factory, GROWING is committed to providing the products with higher speed, higher precision and higher stability to customers to meet their ever-increasing needs.

Our product line contains die-cutting machine, film lamination machine, folder gluer machine, grey board slitting machine, paper bag machine, window patching machine, flute lamination machine,

carton forming machine, and many other products.

- Country: China (Mainland)

- Founded Year: 2021

- Address: K2410, 16/F, Xinguangyingjing, No. 117, Shuiyin Road, Yuexiu District, Guangzhou

- Contact: growing