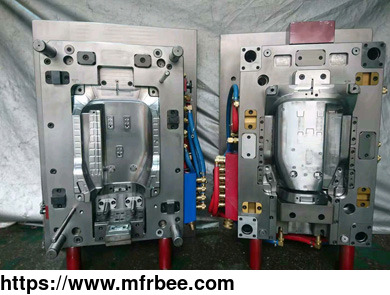

Insert Mould

Specifications

Insert molding is an injection molding process used to encapsulate a component in a plastic part.

The insert custom plastic injection molding process can be divided into two basic steps. First, the component is loaded into the mold before the molding process. Second, it takes the shape of the

part and locks the component into the plastic as molten plastic is injected into the mold.

Features of Insert Mould

Insert molding is the process of inserting a part into a mold prior to the injection molding process. Since the insert injection molding process is the same, different materials are fed into the

mould so as to produce different mould products. The main features of using insert mould by GM-TECH, a reliable injection moulding manufacturer, include:

Improved strength

A strong and reliable attachment point for inserts

Cost-effective compared with other inserting processes

No significant mold changes required

The Specification of Insert Mould

Part material ABS

Cavity 1

Mold accuracy + / - 0.02

Mold steel H13

Moldbase steel 1.1730

Mold life 100W

Mold standard HASCO

Mold structure 3 slides

Exporting country Germany

Leadtime 4 weeks

Mold quality customer satisfaction 98%

FAI pass rate 96%

Project cooperation service customer satisfaction 98%

How does Insert Mould Work?

Insert molding is a powerful tool used to support the form and function of plastic injection molded parts. Insert molding refers to incorporating other parts, particularly metal parts, directly

into the injection-molded product.

For instance, if there are metal inserts that we need to paste it to plastic. We need to place the metal inserts into the insert mold before injecting the plastic. The inserts will be surrounded by

the plastic during the injection process, leaving the insert bonded firmly to the material after cooling and curing.

If you want to know more details of mold technology, please visit our website.

- Country: China (Mainland)

- Address: Shengan Building A, Hengzeng Road Chang'an Town, Dongguan, Guangdong, China

- Contact: Kevin Shaw