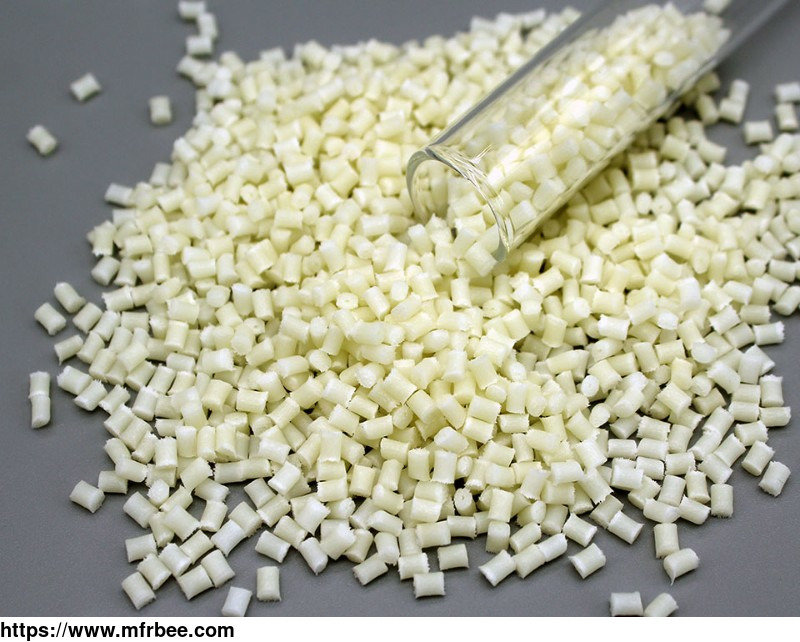

Anmei-PA66 GF for Engineering Plastics

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Anmei focuses on the production of modified engineering plastics.

We have polyamide pa66 modified products with properties of heat-resistant, reinforced, toughened, flame-retardant, wear-resistant, weather-resistant, oil-resistant and conductive.

According to the characteristics of your product, filling with 15%-50% glass fiber to the pa66 base material and other flame retardants, filling, toughening agent via blending extrusion, is

suitable for mechanical parts, shields, wind blades, automobile cooling water tanks, gears, coil bobbin and machine tool accessories and other products.

As one of professional engineering plastic manufacturers, Anmei provides high-quality PA66 plastic for sale. If you are interested, contact us now and find out more information about PA66 material

price.

Types of PA66 GF

PA66 GF15

PA66 GF15 is Nylon66 and 15% Glass-Filled, these materials are performed with medium stiffness and strength but it has much better mechanical properties over unfilled granules.

PA66 GF20

Reinforced with 20% of glass fiber on substrate PA66 is called PA66 GF20, it improves dimensionally stabilized and impacts resistance for injection molding.

PA66 GF30

PA66 GF30 is a polyamide 66 reinforced with 30% glass fibers. It demonstrates outstanding mechanical properties such as high fluidity, high toughness, high-temperature resistance and easy forming.

PA66 GF35

PA66 is nylon 66, namely polyamide 66. GF is glass fiber, generally expressed as PA66+35% GF, that is, 35% glass fiber is added to nylon 66.

PA66 GF45

PA66 GF45 is a 45% glass fiber reinforced polyamide 6.6 with high stiffness and strength.

PA66 GF50

PA66 GF50 is a fiber-reinforced plastic made of nylon 66 resin as a base material and 50% glass fiber as a reinforcing filler, and various processing aids be added to be used in injection molding

products.

Long and short glass fiber PA66 and PA6 introduction

Glass fiber (referred to as GF) reinforcement is an important way of PA modification, which is divided into short glass fiber reinforced polyamide and long glass fiber reinforced polyamide.

Short glass fiber reinforced polyamide, that is, segment glass fiber and nylon are mixed and extruded and pelletized, and long glass fiber reinforced polyamide, that is, glass fiber and nylon,

enter the twin-screw extruder from different positions.

Long and short glass fiber reinforced and unreinforced PA66 and PA6.

Why choose Anmei PA66 GF

Reason One

Selecting qualified raw material factories as Anmei suppliers.

Reason Two

Plastic material in → IQC(Incoming inspection) → Weight the base resin and its additives → Initially mixed through a high-speed mixer → Melt mixed extrusion → Pelletized by the machine → Cooled by

air cooling in a water tank → Cutting → Vibrated and Sieve → Packaging and storage

Reason Three

The entire production process is strictly implemented in accordance with ISO quality operation standards.

PA66 GF in household appliances field

Utilizing the characteristics of heat resistance, wear-resistance and heat resistance of PA, polyamide in the field of household appliances has:

Flame-retardant and toughened PA6 and flame-retardant reinforced PA6 are used for internal structural parts of vacuum cleaners, air-conditioning compressor terminals, fan blades, and microwave oven

junction boxes. The reinforced flame-retardant PPO/PA66 alloy is an ideal material for electric irons and hair dryers because this kind of alloy is resistant to high heat distortion temperatures.

PA6 plus 30% glass fiber (PA6 GF30 plastic) is commonly used as the motor support and roller brush body of a vacuum cleaner due to its high wear resistance and high-temperature resistance. Because

it needs to withstand the continuous impact of high-speed dust and particles, the strength requirement is very high.

If you want to know more kinds of pa6 6 material , please visit our website.

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:

- Address:Qiushe Industrial Zone, Tongli Town, Wujiang District, Suzhou City

- Contact:anmeiplastics .com

Other products from Suzhou Anmei Material Technology Co., Ltd

Relate products of Anmei-PA66 GF for Engineering Plastics

Engineering plastic UHMWPE, PVDF, F46 centrifugal pump with open impeller

Engineering plastic centrifugal pump with open impeller for clear and waste liquids Flow components which contact with liquids are made of ultra-high-molecular weight polyethylene (UHMWPE). The material has excellent corrosion resistance, excellent wear resistance and strong ...