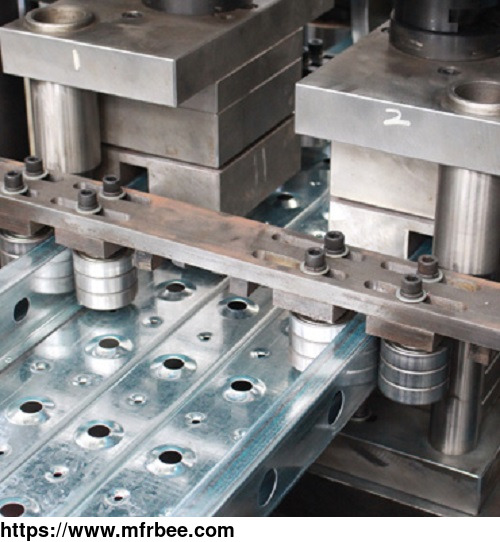

STANDING SEAM ROLL FORMING MACHINE

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Jiangsu Province

- Packaging

- N/A

- Delivery

- 60-90 days

Specifications

With the gradual increase of cold rolling capacity, the consumption of rolls (including work rolls, support rolls and intermediate rolls, etc.) and oil film bearings is also increasing. In this

case, more and more demands are placed on the rolls. It is necessary to transform the roll production management to meet the needs of fast-paced and high-capacity. Standing Seam Roll Forming

Machine can produce more high quality rolls to meet these needs

1. Roll production management system function

The roll production management system functions mainly include subsystem management, assembly management, plan management, grinder fault management, location management, report management, and

communication management. Its core composition is standing seam machine. The component management mainly undertakes the management functions of the rolls, bearings, bearing housings and the like in

the grinding roll room. And the standing seam roll forming machine has high speed rolling shafts and can produce rolls efficiently.

Starting from the new roll into the factory, after each rolling of the unit, grinding to the grinding machine and rolling to the standing seam roll forming machine, until the roll is scrapped, the

whole process tracking management of the roll is carried out. The assembly management consists of two parts: roll, bearing, bearing box assembly management and roll matching management, which

provides proper distribution information for the production of the unit to meet the needs of the production roll.

2. Demand analysis of roll production management system

The position management of the roll production management system divides and defines the roll stacking area in the roll shop according to the roll work type, which is convenient for the operator to

lift the roll. Report management provides users with the means to master the working conditions between the rollers. Interface management mainly develops the corresponding interface with external

systems and designs its content and format. besides, it is very important to have a good standing seam roll forming machine in the roll production management system.

On this basis, the information exchange between computer systems is realized, and the organic connection and cooperative operation between different information systems are achieved. The main

systems that interact with the grinding roll management system include the rolling line L2 system, the control system for the internal grinding machine between the rolls, and the like.

Communication management mainly manages the underlying communication functions between the roll-to-roll management system and other computer systems, thereby enabling data interaction between

systems.

Develop corresponding application receiving programs and maintenance functions, and establish corresponding telegram sub-tables for all interactive telegrams.

BOSJ is a professional china roll forming machine manufacturer,we provides china roll former, guardrail forming machine, standing seam roll former for sale, roll former for sale and etc. Want to

know more? Please contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2008

- Address: No.9 Xiangdun Road, Huashi Town, Jiangyin City, Jiangsu Province

- Contact: Bosj com