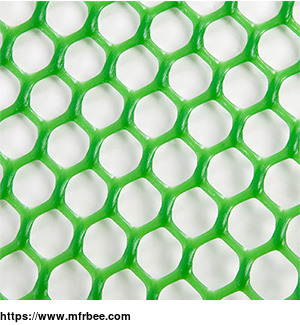

HDPE Flat Net

Specifications

The hdpe net is a food grade plastic raw material (HDPE) which is heated and melted in an extruder, extruded through a screw, and enters an extra-rotary head with a small hole in the surface of the

mold. The molten plastic flows through the pores of the die to form two molten filaments. Because the machine head rotates, the two strands of wire are joined together at one point, and then cooled

and shaped into a net. The extruded plastic mesh has the performances of wear-resisting, corrosion-resisting, fine toughness; it can take the place of metal wire.

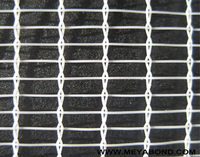

The fine plastic mesh netting is mainly used for aquatic products, poultry breeding, sericulture, civil engineering, sapling protection, garden course protection, railways, highways, roadbed

reinforcement, etc.

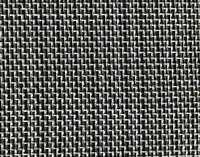

The HDPE mesh net is extruded to diamond and square plastic mesh. Diamond netting is the most common type of extruded plastic netting.

Feature of HDPE Mesh Net

High density polyethylene (HDPE) is made from naturally UV resistant materials

Do not absorb water and will not rot, but have a lower break strength than nylon. It does not absorb water, there is less sag, therefore less adjustments are needed to the net

This plastic net mesh is for high temperature areas, and snowy climates, ultimately ideal for outdoor use.

Used as an electrical insulat

Most products from meyabond are available in bulk rolls or custom cut sizes. Utilize Meyabond's Custom Converting Services to receive the specific sized netting for your needs. Some of these

services include slitting, sheeting, or die-cutting.

Specification of HDPE Plastic Mesh

Mesh opening Mesh shape Weight Color width Length

3mm Diamond, hexagon, square 350gsm-500gsm Black, green, white 1m-2m 50m

4mm Diamond, hexagon, square 350gsm-900gsmas Black, green, white 1m-2m 50m

5mm-50mm Diamond, hexagon, square 350gsm-900gsmas customers required Black, green, white 1m-2m 50m

- Country: China (Mainland)

- Address: Room 449,Xifugang Building, No.53 Lugu Stree, Shijingshan District, Beijing , China

- Contact: meya bond