Automotive Hard Silver Plating

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Place Of Origin

- china

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 30 Days

Specifications

The machined terminal of AP generally adopts a cylindrical structure, primarily using the female terminal as an elastic structure, and its current transmission method usually adopts the form of a

crown spring, hyperboloid spring, and lamella spring and the coating is applying silver material. AP automotive hard silver plating technology is able to be working on every charging interface. And

this hard silver plating technology can effectively extend the service life of your car.

Applicable to IEC charging connector. AP terminals are the perfect solutions for the high current requirements due to their high ampacity and temperature rise stability.

Applicable to SAE chager and it is able to meet the different needs of customers with stable performance. These contacts are the perfect solutions for high current applications. AP's HBS terminals

ensure excellent contact safety and low contact resistance.

AC Charging Pin Connector For GB/T EV Charging Plug

Applicable to GB/T charging connector. AP provides different machine terminals of variable current and structure to meet GB/T charging connector requirements.

Lamella Contact Pins and Connectors

The lamella spring structure is used to transmit current, and the structure is relatively compact. It is specially designed for AC charging bases and DC charging bases of electric vehicles.

Hyperboloid Contacts

The hyperboloid spring structure is adopted to transmit the current. It is a high current, high voltage product and able to be used in clean energy, energy storage, and high current applications.

Crown Spring Pins

Use crown spring structure to transmit current and the multi-spring design makes the elasticity stable. It has the features of low contact resistance, shock resistance, impact resistance, etc., and

is an ideal contact part for connectors.

Automotive Hard Silver Plating Process

Silver Plating is a three-step electrochemical process:

Pre-treat: Wash to remove burrs from the terminals

Electroplating: Precipitate the coating material on the noumenon

Post-treatment: Rinse, wash, seal, neutralize, dry after plating.

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2019

- Address:No.55 Innovative platform, Shaohua Gongfang, Pingliang Dajie, Jianye District, Nanjing

- Contact:au pins

Other products from Aupins Technology Co., Ltd

Relate products of Automotive Hard Silver Plating

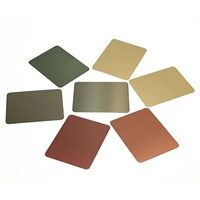

Vibration Silver Plate Sheet Stainless Steel

Vibration Silver Plate Sheet Stainless Steel has a textured surface with a silver color. This finish is achieved by using special brushes or rollers to create a pattern of parallel lines. It is commonly used in architectural applications, such as wall panels, elevator ...

Automotive Hard Silver Plating

The machined terminal of AP generally adopts a cylindrical structure, primarily using the female terminal as an elastic structure, and its current transmission method usually adopts the form of a crown spring, hyperboloid spring, and lamella spring and the coating is applying ...