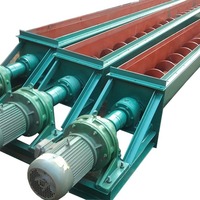

Screw Conveyor

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Spiral Conveyor for Sale

Screw conveyors are divided into two types: shaft screw conveyors and shaftless screw conveyors. They are divided into U-shaped screw conveyors and tube screw conveyors. Axle screw conveyors are

suitable for non-adhesive dry powder materials and small particle materials (eg cement, fly ash, lime, grain, etc.) and shaftless screw conveyors suitable for conveyors made of viscous and

easily-wound materials. (Such as: sludge, biomass, garbage, etc.) The screw conveyor working principle is that the rotating spiral vane transfers the material and conveys it through the screw

conveyor. The force that the material does not rotate with the screw conveyor blade is the weight of the material itself. The friction resistance of the screw conveyor casing to the material.

Spiral blades welded on the rotating shaft of the screw conveyor. The surface shape of the blade has different types such as solid surface type, belt type surface, and blade surface type according

to the material to be conveyed. Spiral conveyor screw axis in the direction of material movement in the end of the thrust bearing with the material to the spiral of the axial reaction force, in the

captain is longer, should be added to the middle of the hanging bearings.

(1) Vertical Screw Conveyor

The screw speed of the vertical screw conveyor is higher than that of the ordinary screw conveyor. The added material under the action of centrifugal force generates friction with the housing. The

friction force prevents the material from rotating along with the screw blade and overcomes the material drop. Gravity, thus achieving the vertical transport of the material. The machine has a

small amount of conveying, small conveying height, high speed, and high energy consumption. It is especially suitable for conveying powdery granular materials with good fluidity, mainly used for

lifting materials, and the lifting height is generally not more than 8 meters.

(2) Horizontal screw conveyor

When the material is added into the fixed machine slot, due to the gravity of the material and the friction between the material and the machine slot, the material accumulated in the lower part of

the machine slot does not rotate with the spiral body, but only moves under the push of the rotating spiral blade, as if The non-rotating nut performs the translational movement of the rotating

screw to achieve the purpose of conveying the material. The machine is convenient for loading and unloading at multiple points, and the mixing, stirring or cooling functions can be completed

simultaneously during the conveying process. Sensitive to overload, easy to plug; The material has crushing loss, the structure of the horizontal screw conveyor is simple, easy to install and

repair and troubleshooting. Suitable for horizontal or slightly inclined (20º below) continuous and uniform conveying loose material, working temperature is -20-+40°C, conveying material

temperature is -20-+80°C. Its rotation speed is lower than that of the vertical conveyor. It is mainly used for conveying materials in horizontal or small angles. The conveying distance is

generally not more than 70 meters.

(3) Spiral tube (roller conveyor) conveyor

Spiral tube conveyor is welded in the cylindrical shell with a continuous spiral blade, rotating with the spiral shell. The added material is rotated and lifted by random shells due to the effect

of centrifugal force and friction, and then slides down along the spiral surface under the gravity of the material, so that the material rotates along with the spiral tube to realize the forward

movement of the material, as if not rotating The screw follows the rotating nut for translational movement to achieve the purpose of conveying the material.

Senotay, as a pulse bag type dust collection system manufacturer, is famous for bag type dust collector and one of professional baghouse manufacturers in China, and bag house for sale here enjoys a

good reputation. Baghouse china dust collector equipment has exported to many

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Europe,Africa

- Address: MOJIABALI VILLAGE WALIWANG TOWN BOTOU CITY CANGZHOU CITY HEBEI PROVINCE

- Contact: Yueqiang Wei