PML Lifting Maganet

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Chongqing

- Packaging

- Carton/Wooden Case/Reel/Bag

- Delivery

- 30-45 days

Specifications

Featured with a built-in strong permanent magnet circuit, TITIANSUHE lifting clamps suppliers permanent lifter magnet is designed to handle steel plates, pipes, and rods simply and quickly without

the help of lifting slings or hoisting. They do not require the use of electricity and are much safer to operate since there is no concern for operation failure due to power shut down.

HVR MAG designs and manufactures lifting magnets for a wide range of applications using permanent, electro-permanent, battery-powered, and electromagnetic technologies. All our industrial lifting

magnets are custom-engineered to pick up, transfer or place ferrous materials regardless of size, weight, or shape, reliably and economically.

These below-the-hook lifting magnets are commonly used in steel mills, scrap yards, loading docks, warehouses, foundries, shipyards, coil and pipe distributors, and other users of applicable steel

products.

This below-the-hook manually switched permanent magnet lifter, for safe and reliable material handling of flat and round steel parts, allows steel handlers to quickly and simply maneuver steel

plates, pipes and rods without the use of slings, chains, and blocking.

Quick View of PML Lifting Maganet PML

Model No.: TC

Capacity: 150kg through 6000kg

Color: Orange paint, other colors are available upon request

Packing: Wooden box

Features and Advantages of PML Lifting Maganet PML

Built-in Strong permanent Magnet Circuit-Provide strong and durable attachment to a steel plate, pipes, and rods.

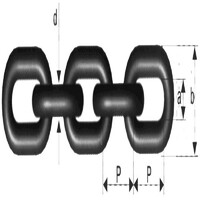

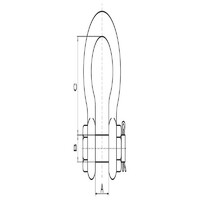

D Shackle Constructed-Can be attached to the hook of lifting equipment directly, no slings or hoisting needed.

Rubber Sleeve Handle-Gives comfortable operation when attaching or detaching the magnet lifter to a steel plate, pipes or rods.

Manually Switched-By simply.

Strong permanent magnetic circuit.

Stable and lasting working performance.

Strong pull-off strength.

Difference safety factors for your choice.

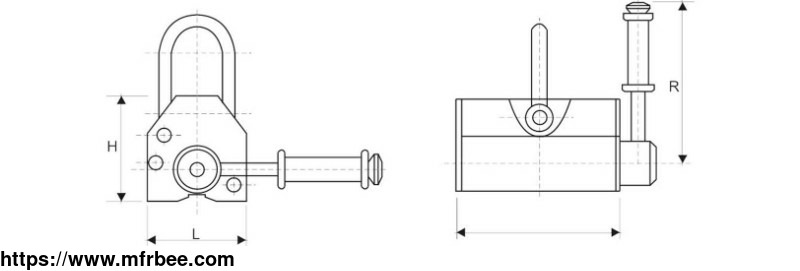

Data Sheet of PML Lifting Maganet PML

Model Rated Lifting

Strength

(Kgf) Cylindrical Lifting

Strength

(Kgf) Max pull-off

Strength

(Kgf) L B H R Operation

temperature

(℃) Net Weight

(Kg)

TC2 150 150 75 300 67 105 62 143 <80 3

TC2 500 500 250 1000 91 209 92 181 <80 10

TC2 1000 1000 500 2000 117 266 122 217 <80 24

TC2 1600 1600 800 3200 163 354 176 285 <80 50

TC2 3200 3200 1600 6400 215 443 234 466 <80 125

TC1 Model safety factor 3:1

Model Rated Lifting

Strength

(Kgf) Cylindrical Lifting

Strength

(Kgf) Max pull-off

Strength

(Kgf) L B H R Operation

temperature

(℃) Net Weight

(Kg)

TC1 100 100 50 300 62 92 67 140 <80 3

TC1 300 300 150 900 92 163 93 180 <80 10

TC1 400 400 200 1200 92 163 93 180 <80 10

TC1 500 500 250 1500 92 210 93 210 <80 14

TC1 600 600 300 1800 120 216 116 220 <80 21

TC1 1000 1000 500 3000 152 264 136 260 <80 38

TC1 2000 2000 1000 6000 172 395 168 375 <80 82

TC1 3000 3000 1500 9000 232 442 221 450 <80 160

TC1 4000 4000 2000 12000 232 575 221 550 <80 220

TC1 5000 5000 2500 15000 296 650 266 700 <80 355

TC1 6000 6000 3000 18000 296 720 266 700 <80 398

As one of magnetic lifters manufacturers, we can offer sorts of magnetic lifting devices for sale, if you are interested, please leave us a message.

As one of lifting equipment manufacturers, we have been engaged in manufacturing lifting equipment for sale, anything you need, please contact us.

If you want to know more types of wire rope hoist, please visit our website.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia

- Founded Year: 2005

- Address: 8-3, A Tower, Xiexing Building, No.59, Hongjin Road, Yubei District, Chongqing, China

- Contact: TITANSUHE TECH