Membrane Switch and Touch Panel

Product Quick Detail

- FOB Price

- USD $5.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Dongguan, Guangdong, China

- Packaging

- According to customer's request

- Delivery

- 14-16 days for sample, 22 days for bulk

Specifications

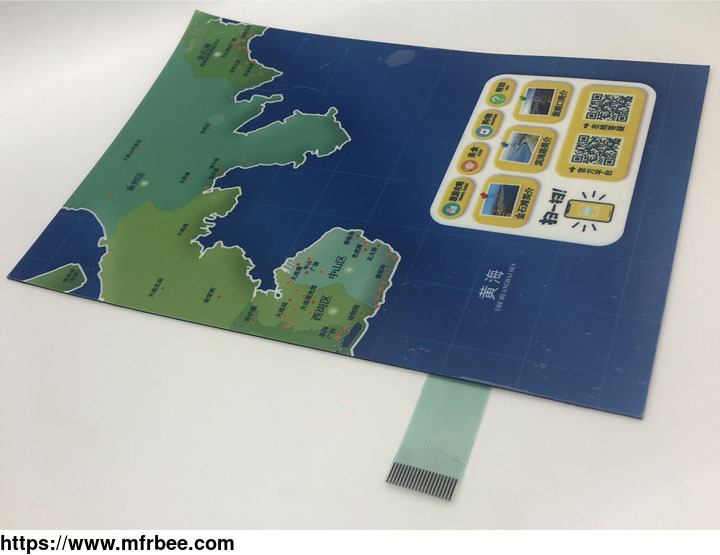

Membrane panel is a type of HMI, in which the structure is generally PET, PC, PVC as the base material, DT, Nitto or 3M as the adhesive material to assemble them together. Membrane switch and panel

is a kind of HMI with more prominent performance and lower prices.

The membrane touch panel is the operating system on many electronic controllers, medical accessories, agricultural products, and it is also the first interface. Color matching and design are

particularly important. Fortunately, as one of the most professional membrane switch panel manufacturers, Niceone-tech's engineers and designers are very good at this type of membrane control

panel. At the same time, we will strictly review whether the customer's drawings and ideas can be realized.

Structual of Membrane Switch And Panel

The structure of the Membrane Switch And membrane control panels is mainly a plane three-layer or multi-layer connection group. The design of the Membrane Switch And Panel is very special. The

traditional membrane switch and panel consists of graphic overlay, upper circuit, isolation layer and lower circuit. They are made on membranes of different materials. At the same time, we can glue

each other with a strong pressure-sensitive glue. After that, we were coated with the covering glue. Then, the user interface for the membrane panel is determined, which also indicates that the

membrane panel assembly has been completed.

Through the touch screen, we can easily judge the tactile and non-tactile membrane touch switches based on the tactile feedback. Therefore, it is very important to choose a qualified membrane

switch panel manufacturer.

Niceone-tech Membrane Touch Control Panel Features

The membrane switch and panel is generally thin, if not specially required, the thickness is controlled between 0.7-1.2mm. If the material is too thick, Niceone-tech will advise customers to use

stainless steel molds, otherwise, the shape cannot be punched out. Even because the material is too thick, die-cut tooling cannot be used for punching.

Membrane panel:

With a sealed surface, easy to clean and affordable

Can be customized in various shapes and surfaces

Has a big application scope

In recent years, Niceone-tech is committed to researching and developing new types of membrane switches. LGF membrane panel not only has the life of fiber membrane panels but also cheaper than EL

membrane panels. At the same time, its uniform luminescence and long life make it very popular in European and American countries.

On this basis, we have also developed a Resin dome membrane switch, the main feature is that the appearance and buttons are very beautiful. But the price will be relatively high, and the thickness

will be thicker.

As one of the leading membrane switch panel manufacturers, Niceone-tech can offer custom membrane touch and control panels for various usage. We have the marine membrane switch and panel, membrane

touch and control panel, etc. that can meet high-end requirements.

Niceone-tech Membrane Switch And Panel Advantages

At this time, there will be two types of printing methods to overlay the top structure of the membrane panel. Using different screen printing methods will affect cost, usability, and durability. A

poor printing method will make the membrane panels coating of membrane switch overlay easy to peel off. Therefore, Niceone-tech has always been committed to quality, and we will pass the 100 grid

test every time the screen printing and color printing are performed to prevent the product from peeling off the coating. Fortunately, Niceone-tech has mastered the core technology, which makes the

product ink and circuit-level ink have high viscosity characteristics, and the above problems will not easily occur.

The CMYK color printing method can form gradual patterns or colors. Generally, we call this kind of digital membrane switch. The gradual color is not possible with conventional screen printing. At

the same time, because color printing is very suitable for bulk goods when the quantity is large, the use of color printing will reduce the cost, but the color error of color printing will be

larger. However, the general membrane switch and panel is produced by CMYK color printing. If it is a PET circuit, screen printing is still required.

Screen printing, the most commonly used printing method for membrane switch, uses ink debugging to produce a variety of colors, endowing the products with different colors. But when more colors are

involved, we need more screens to create images. Meanwhile, Niceone-tech will choose different screens to produce different circuits to achieve high-precision and low-error circuits products.

Screen printing is suitable for small batch production, and it also has higher color requirements and lower error rate. Even sometimes we will adopt the combination of screen printing and CMYK

color printing so that a high-quality digital membrane switch with advantages of the two can be formed.

There are many custom membrane keypad manufacturers, but we are one of the best choices for you.

- Country: China (Mainland)

- Address: NO.61, Jianghai Road, HuangJiangTown, Dongguan, Guangdong, China

- Contact: Niceone tech