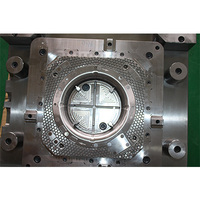

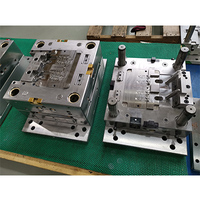

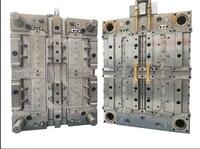

Plastic Parts Gallery

Product Quick Detail

- FOB Price

- USD $5,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Baoan District, Shenzhen. China.

- Packaging

- PALLET

- Delivery

- 4 weeks

Specifications

It is a complex task to design plastic parts involving many factors according to varoius requirements for different industires. "How is the part to be used?" "How does it fit to other parts in

the assembly?" "What loads will it experience in use?" The plastic injection molds if classified from product function, various different plastic parts can be produced by injection molding:

Plastic automotive parts include door panel, door handle, base door, dashboard panel, instruments panel, front and rear step pedal, centre panel, chair panel, front and rear bumper, wheel cap,

wheel cover, wheel brow, cup holder, belt cover, front grille, grille radiator, rain tray, main panel housing, mirror cap, fan, filter, air vent, license plate frame, side fender, seat fittings,

seat travel tray, mirror housing, auto headlamp holder, rear light shell, brake light, steering system, lever column, alternator cover, worm wheel, ball retainer, reservoir and cap, brake fluid

reservoir, water pump impellers or pulleys, water tank, signal switch hsg, air conditioner parts, glove box, speaker cover, engine parts, console parts, mudguard, trim strip, gear shift cover, bump

stopper.

Medical devices' plastic parts include disposable medical parts, lab equipment, dental equipment, atomizing switch, blood glucose measuring instrument, ultrasonic instrument, blood pressure

measuring instrument, beauty equipment.

Home appliances plastic parts include small kitchen appliances, coffee machines plastic parts, fryer cooker, kettle plastic parts, food processor, toaster, vacuum cleaner, blenders plastic

components, clocks plastic housing, steamer accessories, cleaner plastics, heating, cooling & air purifier, remote controller, large appliances, wash machine parts, home projectors, refrigerator

plastic components.

Industrial plastic parts include industrial wheels, industrial gears, plastic storage bins, plastic industrial tanks, plastic valves, plastic connectors, industrial fan, etc..

Electrical Molding Parts include all the electronic plastic parts and electrical plastic accessories.

In addition to functional and structural issues, processing issues play a large role in the design of an injection molded plastic part. How the molten plastic enters, fills, and cools within the

cavity to form the part largely drives what form the features in that part must take. Adhering to some basic rules of injection molded part design will result in a part that, in addition to being

easier to manufacture and assemble, will typically be much stronger in service. Dividing a part into basic groups will help you to build your part in a logical manner while minimizing molding

problems. As a part is developed, always keep in mind how the part is molded and what you can do to minimize stress.

As one of the injection moulding companies, we provide custom plastic injection molding china, plastic injection molding medical parts, injection mold building, plastic injection molding and etc.

Want to know more about how to make plastic parts at home? Please contact us.

- Country: China (Mainland)

- Founded Year: 2011

- Address: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen. China.

- Contact: Yoyo Tang