Grinding Mill Used in Aluminum-plastic Separation Line

Product Quick Detail

- Place Of Origin

- 中国

- FOB Price

- USD $9,999.00 / Piece

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

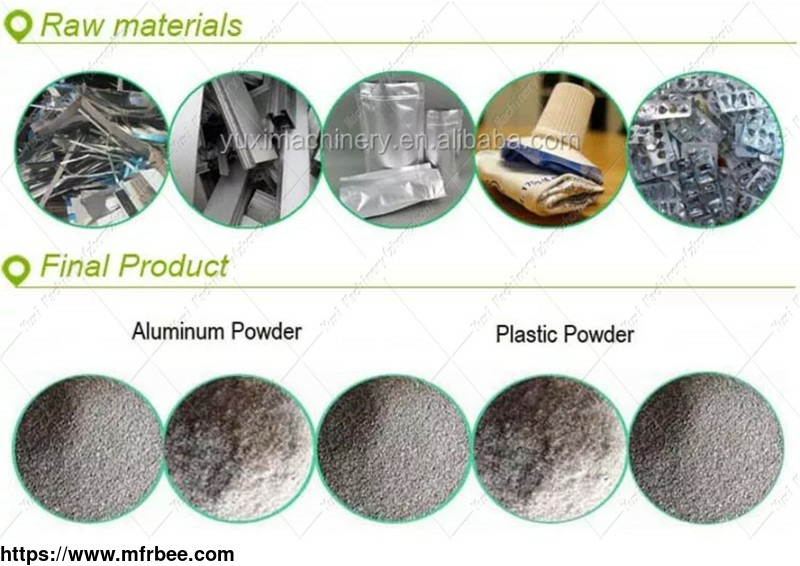

The aluminum-plastic grinding mill is the core equipment in the aluminum-plastic separation line. The aluminum-plastic mill is divided into high-pressure suspension roller mill and high-pressure micro-powder mill according to the different grinding fineness of the material. The aluminum-plastic separating line can carry out metal separation for different aluminum-plastic composite materials. Since the aluminum-plastic mill in the aluminum-plastic separation equipment works in a dusty environment for a long time, this requires regular maintenance.

Maintenance of Aluminum-plastic Mill for Aluminum-plastic Separation Equipment

1. The bearing bears the full load of the mill machine, so good lubrication has a great relationship with the life of the bearing. The bearing directly affects the service life and operating rate of the machine. Therefore, the injected lubricating oil must be clean and the seal must be good.

2. Newly installed wheels are prone to loosening and must be checked frequently;

3. Pay attention to check the wear degree of wearable parts, and replace worn parts at any time;

4. The bottom frame plane of the movable device should remove dust and other objects to prevent the movable bearing from moving on the bottom frame when the machine encounters unbreakable materials, resulting in serious accidents.

Installation and Commissioning of Aluminum-plastic Mill for Aluminum-plastic Separating Line

1. The grinding equipment should be installed on a horizontal concrete foundation and fixed with anchor bolts; after installation, check whether the bolts in each part are loose and whether the door of the main engine is fastened;

2. When installing, pay attention to the verticality of the main body and the horizontal;

3. Configure the power cord and control switch according to the power of the equipment;

4. After the inspection is completed, carry out a no-load test run, and the production can start after the test run is normal.

Aluminum-plastic separation equipment is ideal equipment for the recycling of waste aluminum and plastic materials. The aluminum-plastic separating line completely adopts mechanical separation methods, and is completely dry separated, and the separation purity rate is above 99%. The aluminum-plastic separating line

https://www.shreddingtech.com/waste-recycling-lines/waste-pcb-recycling-lines.html

https://www.shreddingtech.com/waste-recycling-lines/scrap-cable-wire-recycling-machine.html

https://www.shreddingtech.com/waste-recycling-lines/automatic-scrap-radiator-recycling-machine.html

- Country: Afghanistan

- Contact: Peng Sara