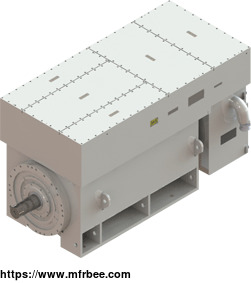

VFD Motor

Product Quick Detail

- FOB Price

- USD $100,000.00 / Piece

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 60 Days

Specifications

What is a VFD motor? Variable frequency drive (VFD) is a kind of power control equipment which uses frequency conversion technology and microelectronics technology to control AC motor by changing

the speed of motor. The VFD is mainly composed of rectifier (AC to DC), filter, inverter (DC to AC), drive unit, detection unit, micro processing unit, etc. VFD motor is a combination of variable

frequency drive and three-phase motor to be used with AC 50Hz/60Hz power supply system. The VFD motor can adjust the speed of motor under various load conditions, completely eliminate the

mechanical and electrical shocks and prolong the service life of mechanical equipment. And the variable frequency drive motor also works to protect against overload, overvoltage, undervoltage,

phase loss and overheating.

Types of Variable Frequency Drive Motor

Flame Proof Asynchronous VFD Motor

The power rating range of this kind of VFD motor is from 55kW to 3000kW and it can be designed as per IP 56 or higher which is able to withstand a certain degree of flooding.

PM Integrated VFD Motor

PM integrated VFD motor combined VFD and motor,can supply a big torque even in low speed.it can output most of VFD/motor parameters and curves to distribute control system.

High Ingress Protection VFD Motor

High Ingress Protection VFD motor is mainly used in excavators in the field of construction machinery, port bucket wheel stacker-reclaimer, and etc.

Flameproof Permanent Magnet Motorized Pulley

The pulley is a kind of motor with is used for conveyor. Voltage is from 380V to 1140V and power rating is less than 300kW.

VFD Motor Efficiency

Motor efficiency does change as speed and torque change and is also affected by voltage harmonics present in the VFD motor output. The magnitude of losses due to voltage harmonics will vary with

the motor design. VFD motor efficiency decreases with decreasing motor load. The decline in efficiency is more pronounced with VFD motor of smaller horsepower ratings.

How does a VFD Control Motor Speed?

A variable frequency drive controls the motor speed by using PWM (Pulse Width Modulation) to alter the power supply frequency that's fed to the motor. The first step in this process is to convert

the AC supply voltage into DC by the use of a rectifier. DC power contains voltage ripples which are smoothed using filter capacitors.

How to Change Motor Rotation on a VFD?

It is usually easy to change the direction of rotation with the VFD itself. Most VFD's have a simple toggle command for forward and reverse. Switching two of the power leads coming out of the VFD

can solve the problem of which the motor is shut down and later restarted, it will restart running backwards again.

Application of the VFD Motor

The VFD motor can run in the explosion environment. Flameproof and intrinsically safe high-voltage integrated VFD Motor is a highly integrated product of the motor and the drive. It is widely

applicable to belt conveyors, loaders, AFC's, emulsion pumping stations, and other equipment used in underground coal mining to achieve a soft-start under heavy load and dynamic speed control. CCS

can offer a wide range of VFD motors for different scenarios, including motor with integrated VFD, VFD rated motors, VFD multiple motors, and other VFD compatible motor.

How to Select a VFD Motor

Choose the appropriate structure form of protection grade motor according to the application place.

Choose the appropriate power and voltage level according to the responsible ability.

According to the environmental temperature, humidity, above seal level, dust and gas conditions, special requirements such as explosion prevention are selected.

Choose a strong manufacturer to ensure the material quality and production process to the maximum extent.

For more information about transmission substation equipment and changing motor rotation on a vfd, please feel free to contact us!

- Country: China (Mainland)

- Address: 3138 Shiji Avenue, Huangdao District, Qingdao, China ,266000

- Contact: ccs motors