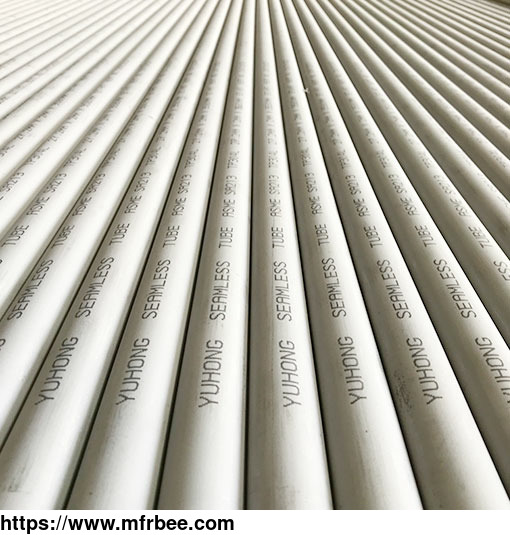

TP316/TP316L/TP316H STAINLESS STEEL SEAMLESS TUBE

Specifications

As one of the most popular steel grades, 316 has excellent corrosion resistance, atmospheric corrosion resistance, and high-temperature strength due to the addition of Mo, and can be used under

harsh conditions; excellent work hardening (non-magnetic); excellent high-temperature strength; Non-magnetic in solid solution state; Good gloss and beautiful appearance of cold-rolled products.

316 stainless steel pipes are widely used in industrial transportation pipelines and mechanical structural components such as petroleum, chemical, medical, food, light industry, mechanical

instrumentation, etc. In addition, when the bending and torsional strength are the same, the weight of 316 ss pipe tube is lighter, so it is also widely used in the manufacture of mechanical parts

and engineering structures.

316 STAINLESS STEEL TUBE SPECIFICATIONS

Steel Grade 300 Series, 316 Type Seamless, Round Pipe/Tube

Standard ASTM, AISI, GB, DIN, JIS Certification ISO, SGS, BV, ISO/CE/SGS

Length 3000-6000mm, Customized Thickness 0.41-12.7mm

Technique Cold Rolled, Cold Drawn Min./Avg. Min./Avg.

Outer Diameter 3.2-127mm, Customized Finish Brush Polish Cold Drawn, Pickled, Bright Annealed

CHEMICAL PROPERTIES OF 316 STAINLESS STEEL SEAMLESS TUBE

Chemical Composition C Mn P S Si Cr Ni Mo

316 0.08 2 0.045 0.03 1 16-18 10-14 2-3

MECHANICAL BEHAVIOR OF TP316/TP316L/TP316H STAINLESS STEEL SEAMLESS TUBE

Mechanical Behavior TS YS Elongation

MPa MPa %

316 515 205 35

TP316/TP316L/TP316H STAINLESS STEEL SEAMLESS TUBE HIGHLIGHT

The corrosion resistance of tp316l stainless steel pipe is better than that of 304 stainless steel pipe, and the 316 stainless steel pipe has good corrosion resistance in the production process of

pulp and paper. 316 stainless steel is also resistant to erosion by marine and aggressive industrial atmospheres. Heat resistance In intermittent use below 1600 degrees and continuous use below

1700 degrees, 316 stainless steel has good oxidation resistance. In the range of 800-1575 degrees, it is best not to use TP316/TP316L/TP316H stainless steel pipe continuously, but when 316

stainless steel is used continuously outside this temperature range, the stainless steel has good heat resistance.

316 stainless steel pipe has good weldability. All standard welding methods can be used for welding. According to the application, 316Cb, 316L, or 309Cb stainless steel filler rods or electrodes

can be used for welding. In order to obtain the best corrosion resistance, the welded section of 316 stainless steel needs to be post-weld annealed. Post-weld annealing is not required if 316L

stainless steel is used.

As a 316 stainless steel pipe supplier, we will provide more kinds of related products for sale, if you have needs, please contact us.

- Country: Afghanistan

- Business Type: Manufacturer

- Market:Oceania

- Founded Year:

- Address:Room 1005--1007, No.1 New World Building, NO.1018 Min'an Road, Yinzhou District, Ningbo, China

- Contact:YUHONG .com