FRICTION STIR WELDING IN AUTOMOTIVE INDUSTRY

Specifications

FRICTION STIR WELDING IN AUTOMOTIVE INDUSTRY

The development of new energy vehicles in the world started with hybrid power, and then gradually entered the era of battery-based vehicles. Pure electric and plug-in hybrids have become the main

policy support for new energy. Since 2013, new energy vehicles have developed rapidly with the promotion of support policies from various countries. In 2021, the global sales of new energy

passenger vehicles including pure electric, plug-in hybrid, and fuel cell vehicles will be 6.23 million, a year-on-year increase of 118.6%. China has put forward the strategy of "energy-saving and

new energy vehicles", and pays great attention to the research and development and industrialization of new energy vehicles. Under the premise of advocating global environmental protection today,

the new energy vehicle industry will definitely become the orientation and goal of the future development of the automotive industry.

BATTERY TRAY FOR ELECTRIC VEHICLE

The aluminium alloy battery tray / lower box of the battery pack is mainly made of steel and aluminium alloy. Aluminium alloy is favored by more and more automobile OEMs and manufacturers around

the world because of its low density and various forming processes, which can meet the requirements of electric vehicle lightweight. At present, the aluminium alloy battery tray has two process

schemes: integral casting and aluminium profile welding. Friction stir welding and process has been widely used in the manufacture of battery trays because of its non-melting, automation,

intelligence, environment-friendly and integrated characteristics.

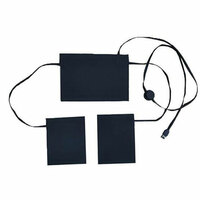

COLD ALUMINIUM PLATE

The main materials of friction stir welding water-cooled plates are aluminium alloy and stainless steel. Aluminium alloy can meet the lightweight requirements of the application end due to its low

density and various forming processes.

CASING WITH FRICTION STIR WELDING FSW COOLING/COLD CHANNEL

The main processes of aluminium alloy motor shells include aluminium extrusion forming and friction stir welding.

There are many custom die casting manufacturers, but we are one of the best choices for you.

- Country: China (Mainland)

- Address: Part Of The West Factory Building, Building 8, No. 2, Yunsheng Technology And Industry Park, Canghai Road ChinaZhejiang

- Contact: Cheeven com