Anpeng Screening Media

Specifications

Our high-performance woven industrial mesh screen, self-cleaning wire screen, and PU-Mesh are tailored and customized to meet your specific screening challenge. Years of examinations and

innovations of wire mesh screen material made Anpeng one of the best wire screen suppliers worldwide.

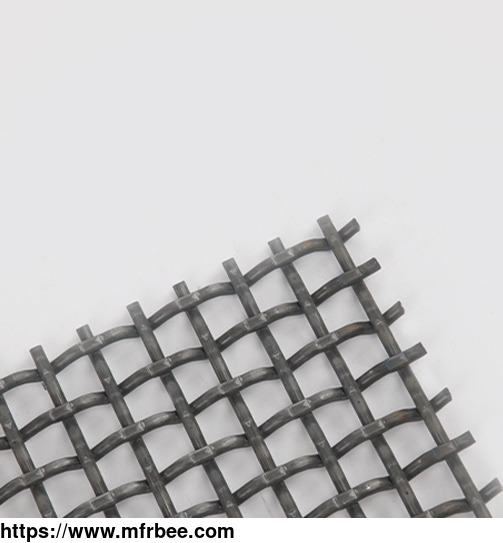

Woven Wire Mesh

Available in Square and Slotted Meshes, High quality wire mesh screen material used in production and a wide range of wire diameters and openings ensuring their cost-effective work in almost any

applications.

Square Mesh

Square Mesh is a versatile screening media which is easy to install and maintain.They are the most commonly used opening shape in standard applications.

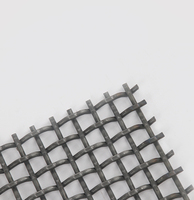

Slotted Screen

Slotted weave meshes are designed to offer high prodcution by providing a greater percentage of open area and greater wear life.

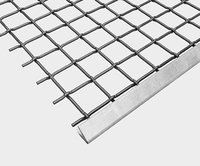

Anti-clogging Screen

Anti-clogging screens with special weaving pattern enable wires to vibrate independently at different frequencies, preventing material accumulation, and allowing the anti-clogging effect.

Self-cleaning Screens

Designed to be the Perfect Solution for wire mesh screen material with low flowability that are though to screen. Eliminate blinding, pegging and clogging problems due to its special structure and

combinations of steel wires and Polyurethane bars.

Diamond Opening Screen

Our most popular self cleaning screen mesh. It is similar to traditional square openings meshes, but with greater open area and increased throughput, providing precise material stratification and

cleaner product.

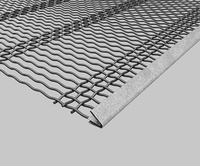

Wave Opening Screen

Made with crimped wires placed parallel to each other, best used for severe blinding application, large open area offers effective sizing control, ideal for the removal of super fine materials and

etc.

Triangle Opening Screen

Unique combination of crimped and straight wire form the triangular opening shape to absorb impact, and improve accuracy of sizing. This is a perfect replacement of traditional fine mesh.

Harp Screen

Designed to have the maximum open area, most efficiently in removing sand, gravel, topsoil, fines and etc.

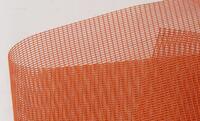

PU Mesh

Ideal for the classification of high-humidity or wet materials because of the Polyurethane coating on the wires. PU-Mesh is extremely light, flexible, easy to install and waterproof with improved

wear life and high cost-effectiveness.

Square PU Mesh

PU-Mesh Screens are steel braided wire mesh coated with abrasion-resistant polyurethane in either fully welded or partially welded style. Light and flexible, which makes the PU Mesh extremely

impact resistance.

Slotted PU Mesh

Slotted PU Mesh Screens has slotted openings, and greater open area than Square PU-Mesh and therefore higher throughput.

Wire Mesh Screen Materials Available for Anpeng

As an industrial screen manufacturer, we use High Tensile Steel that is abrasion resistant, which is ideal for applications facing significant wear such as filtering rocks, sand and gravel.

Polyurethane: is known for its high load bearing capacity in both tension and compression, and its abrasion and impact resistance property, Polyurethane is extremely wear proof in challenging

applications even at very low tempreture.

High Tensile Steel Wires For Anpeng Wire Mesh

High Tensile Steel Wires

Compare to common carbon steel, high tensile steel contains additional alloys like silicon, manganese, chromium, and nickel. That's why it is abrasion resistant, which is ideal for applications

facing significant wear such as filtering rocks, sand, and gravel.

Now the price of wire mesh screen for sale is reasonable, if you have needs, please contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Americas,Europe,Asia

- Founded Year:2001

- Address:No. 12 Weiyi Rd, East Wire Mesh Industrial Zone, Anping County, Hebei, China

- Contact:ap screens