Anpeng Harp Screen

Product Quick Detail

- Minimum Order

- 2500

- Packaging

- N/A

- Delivery

- 21 Days

Specifications

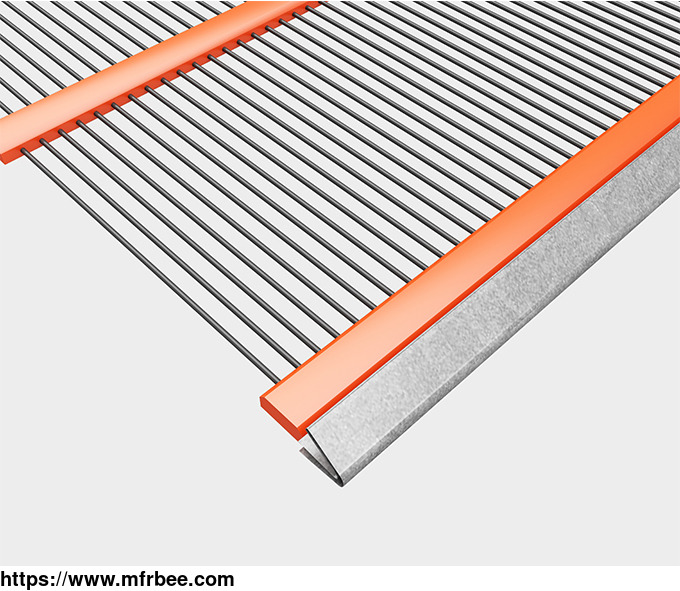

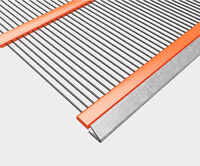

The self-cleaning harp screen has the maximum open area in all Anpeng self-cleaning screen mesh series. Like the traditional harp screen mesh or piano wire screen, the self-cleaning harp wire

screen is best for desanding or removing fines while maintaining material in size. It is most efficient in dry screening of sand, gravel, loam, topsoil, mulch, compost, golf sand and more.

Specification of harp wire screens

Item No. Opening (mm) Wire Size (mm)

1 4 2

2 5 2

3 8 2

4 10 2

5 12 2

6 5 2.34

7 5 2.5

8 6.35 2.67

9 9.53 3.05

10 12.7 3.05

11 5 3.15

12 12.7 3.43

13 12.7 3.76

14 6 4

15 15.88 4.11

16 12 5

17 16 6

18 22.4 8

19 25 8

Features of Anpeng Harp Wire Screen

1

Maximum open area

2

Significantly increase efficiency in dry screening of sand gravel, loam, topsoil, mulch, compost, golf sand and removing of fines.

3

Offer some sizing control

Advantages of Harp Wire Screens

1

Most open area of any screen type

2

Improve the screening efficiency

3

Increase throughput

4

Many apertures and wire diameters available

Anpeng Harp Wire Screens Service Life

The service life of self-cleaning screen depends on three core factors:

1.

The quality of the steel Considering the importance of carbon content on the wear resistance, Anpeng harp wire screens require at least 0.5% carbon. The quality of the polyurethane materials used

in the making of the PU bars that binds the wires together in our self-cleaning seris and PU-mesh.

As one of industrial screens manufacturers, we can offer kinds of industrial wire screens for sale, more details, please visit our website.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Americas,Europe,Asia

- Founded Year:2001

- Address:No. 12 Weiyi Rd, East Wire Mesh Industrial Zone, Anping County, Hebei, China

- Contact:ap screens

Other products from Anpeng Wire Mesh Filter Equipment Co., LTD

Relate products of Anpeng Harp Screen

Anpeng Harp Screen

The self-cleaning harp wire screen has the maximum open area in all Anpeng self-cleaning screen mesh series. Like the traditional harp mesh or piano wire screen, the self-cleaning harp screens is best for desanding or removing fines while maintaining material in size. It is ...