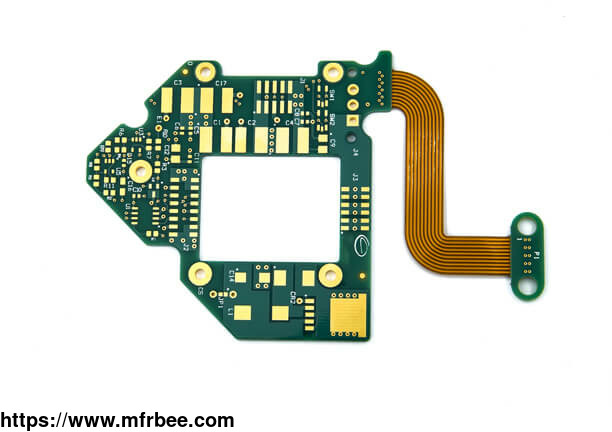

Rigid Flex PCB

Product Quick Detail

- FOB Price

- USD $30.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- ShenZhen

- Packaging

- N/A

- Delivery

- 5 days

Specifications

Fastlink helps customers finish a lot of projects including smart phone, smart TV, tablet pc, laptop, smart wearable devices, TWS etc. We can produce a maximum 24L rigid pcb plus 8 layer flex pcb.

Customized rigid flex pcb can safely bend into small and complicated electronics, making them suitable for modern devices like smartphones. Because of their good performance in absorbing shock and

vibration in high stress environment, they are more and more widely used.

Fastlink Electronics' professional engineers combine standard circuit board construction with flexible design, which is suitable for situations requiring more durability. We have successfully

provided our customers with tens of thousands of excellent manufacturing cases of flex rigid board.

What Are The Applications Of China Rigid Flex PCBS

Quick turn rigid flex pcb not only maximizes space and weight but also greatly improves reliability, eliminating many of the needs for solder joints and fragile and fragile wiring prone to

connection problems. So the rigid flex design PCB is more and more widely used in various fields, from smart devices to mobile phones and digital cameras. Because of its excellent weight reduction

ability, the Rigid-Flex PCB is also increasingly used in medical devices such as pacemakers. There are also intelligent control systems and electrical applications, including test equipment, tools,

cars, etc,

Benefits of China Rigid Flex PCB

01.

Cost Savings

The reduced size makes it easier to fit more components into a smaller space. This actually helps reduce overall system costs. Additionally, because they require fewer interconnections and

associated parts and components, these flexible boards can also prove to be more reliable and require less maintenance during long-term operations.

02.

High Temperature Resistance

For pcb design and fabrication manufacturer, like all types of flexible circuit boards, rigid flexible printed circuit boards perform well in even the harshest environments, especially at extreme

high temperatures. The rigid flexible plate is also easy to test, making it ideal for prototyping.

Established in 2009 with the original aspiration of providing "assured prodcuts, thoughtful services", Fastlink has been concentrated on PCB layout, PCB and PCBA fabrication, turnkey assembly,

and components sourcing services. We aim at solving problems and providing reliable solutions for customer in different areas. Located in Shenzhen we produce PCB over 30,000 types and assembly

10,000 designs per year.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2009

- Address: A310, HuaFeng Bussiness Building, Xixiang Rd, Bao'an, ShenZhen

- Contact: fastlink electronics