Quick Change Disc

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 10000

- Packaging

- N/A

- Delivery

- 60-90 days

Specifications

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2015

- Address:No. 61, Qinfen Road, Xinbei District, Changzhou, Jiangsu Province, China.

- Contact:Lio Zhao

Other products from CHANGZHOU RMN ABRASIVES CO., LTD

Relate products of Quick Change Disc

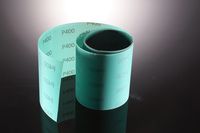

Quick Change Discs RMC wool wheelquick change disc is great for many different types of polishing and buffing projects, which could be used on wide variety of surfaces - stainless steel and other metals, wood, chrome, synthetics and so on. Specification of Quick Change Sanding ...

Quick Change Grinding Disc RMCquick change abrasive discs have good performance for general use and moderate pressure usage. Easy fastening and swapping of quick change discs enhances tool efficiency and worker productivity. Specification of Quick Change Grinding Disc Name Item ...

Quick Change Disc RMC quick changepsa disc are ideal for clearing welds, removing corrosion, rust, scale, paints, without compromising the geometry of the workpiece thus leaving a clean manageable surface to work on. We have quick change grinding disc, quick change sanding ...