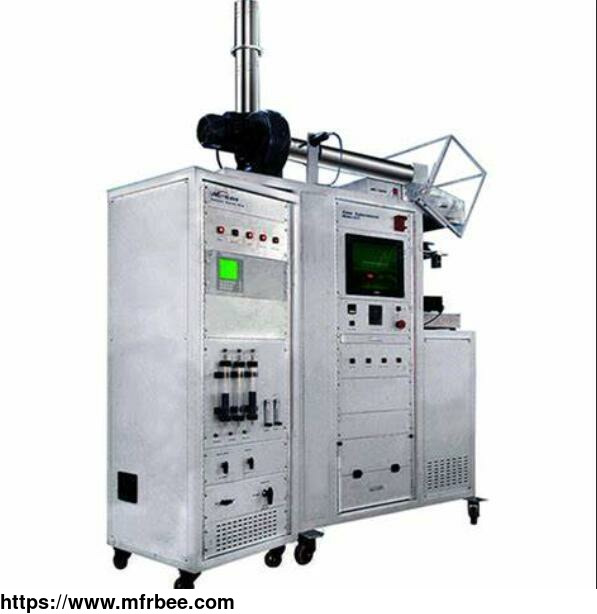

ISO 5660 Cone Calorimeter

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- Wooden case packaging

- Delivery

- 15 Days

Specifications

ISO 5660 Cone Calorimeter

Cone calorimeter is able to determine parameters such as Ignition Time, Heat Release rate, Mass Loss, and other properties relevant to fire characteristics. It complies with ISO 5660; ASTM E1354; BS 476 Part 15, etc. It is the most widely used instrument in Building material, Rail, Cable and wire, etc.

ISO 5660 Cone Calorimeter is a modern device used to study the fire behavior of small samples of various materials in condensed phase. Heat Release Rate, Mass loss rate, CO and CO2 generation, Oxygen consumption .etc will be tested. It is widely used in the field of Fire Safety Engineering.

Application:

* Building Materials

* Rail

* IMO

* Wire & Cable

* Other

• ISO 5660

Reaction to fire tests – Heat release, smoke production and mass loss rate

• ASTM E 1354

Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products Using an Oxygen Consumption Calorimeter

• BS 476 Pt.15

Fire tests on building materials and structures – Method for measuring the rate of heat release of products

Features:

1. ISO 5660 Cone Calorimeter with movable analysis cabinet, can be connected with a large heat release rate test system such as ISO 9705, EN 13823, etc, complied with ISO 5660, ASTM E1354, BS 476 Part 15, etc. testing standards.

2. Integrated test body and 19 inches analysis cabinet, embedded PC 15 Inch Touch screen computer, for the whole control and automatic testing.

3. Conical heater rated power 5000W, the heat output of 0 ~ 100kW/m2, using PID temperature controller, while the radiation cone can be horizontal or vertical.

4. Exposed to the central part of the surface of the sample 50 x 50mm range, radiation at the center of the deviation is not more than 2%.

5. The sample weighing range is 0 ~ 3000g, accuracy: 0.1g.

6. Auto Split Shutter automatically opened to transmit radiation to the sample.

7. ISO 5660 Cone Calorimeter is equiped with ABB EL3020 Paramagnetic oxygen analyzer, using the method of paramagnetic change to measure the concentration of oxygen in the gas. The concentration range of 0-25%.

8. Smoke density analysis using a laser system, system consists of a 0.5mW He Ne laser, the main detector, and auxiliary detector.

9. The exhaust system consists of the fan, the smoke collection cover, the exhaust pipe and orifice plate flow meter, and so on. Exhaust fan flow rate of 0 ~ 50g/s, precision 0.1g/s.

10. A ring sampler has been installed from the smoke collecting hood at 685 mm, with 12 holes.

11. The exhaust flow rate should be determined by measuring the pressure difference on both sides of the sharp edge orifice 350 mm above the fan, the inner diameter of the sharp edge orifice plate is 57mm + 1mm.

12. ABB SCC-S Gas sampling system comprises sampling pump, filter, cold trap, wastewater discharge, water filters, and CO2 filters.

13. Portable water cooling system without the need for waterworks and plumbing when using the Heat Flux meter (for ISO 5660).

14. In order to calibrate the response of the whole test system, the use of a square opening brass calibration burner was used to measure the value of the C- coefficient.

15. The data acquisition system is able to record oxygen analyzer, orifice meter, thermocouple, and other instruments of the output.

SOURCE:https://www.standard-groups.com/en/FlammabilityTesting/699.html

TAG:cone calorimeter,skyline: cone calorimeter,calorimeter,cone calorimeter test,cone calorimeter method,skyline: cone calorimeter,en 45545-2 cone calorimeter,cone calorimeter simulation,heat release cone calorimeter,heat release rate (cone calorimeter) testing machine,astm e1354 heat release cone calorimeter,cone calorimeter fire testing equipment,cone calorimeter heat release test machine,cone calorimeter with imported oxygen analyzer,#conecalorimeter,cone test

#conecalorimeter #skyline: conecalorimeter #calorimeter #conecalorimetertest #conecalorimetermethod #skyline:conecalorimeter

- Contact: kevin blant