Inline X-Ray Inspection Machine

Specifications

In the inspection process of electronic components, the PCB seamark x ray inspection machine can be directly connected to the SMT production line for high-capacity automatic inline full inspection,

it can be used offline with unloader and loader. PCB welding x ray machine price is very reasonable. Fully automatic judgment and inspection are carried out for the characteristic area of the

circuit board or the designated device. The automated inline X-ray inspection machine supports fully automatic inline inspection of IC, BGA semiconductor devices, SMT and PTU packages, sensors and

other fields.

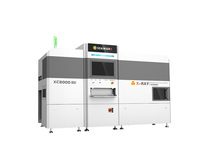

Seamark Inline X-Ray Inspection Machine

XL6500 Inline X-Ray Inspection Machine

XL6500 is an SMT inline micro-focus X-ray inspection equipment for electronic components. It can be directly connected to the SMT production line, or it can be used offline with the loading and

unloading conveyors.

How does an Inline X Ray Machine Work?

The X-Ray inspection equipment uses high-voltage accelerated electrons to release x-rays that penetrate the sample and leave an image. The technician observes the relevant details of the sample

through the brightness of the image.

What Is X-Ray Printed Circuit Board (PCB) Inspection machine?

Across different fields, from aerospace to aquatic to clinical manufacturing, x-ray PCB inspection machine is used to discover covert flaws in solders and various other manufacturing errors, which

are unseen to ordinary optical inspections. Utilizing x-rays to determine errors, minor or significant, x-ray PCB inspection equipment does not damage the board under inspection.

The aspects that make PCB inspection a challenging affair consist of:

Surface Mount Technology

The Surface Mount technology has actually led to smaller packages as well as leads. These, consequently, make PCBs denser, with numerous parts concealed between the layers.

Size of the components

Miniaturization of motherboard elements is currently a pattern in electronics production. Currently, there's an excellent need for denser boards, which has exerted pressure on the manufacture of

PCB components.

Placement of Components

There's a wonderful demand for smaller as well as layered equipment to save on room as well as make the best use of capabilities. As a result, lots of components as well as solder joints are being

placed within the internal layers of electronic devices.

These complex needs, as well as designs, make it hard for common inspection techniques such as ultrasonic, optical, and thermal imaging to supply detailed fault-finding images. To get rid of these

difficulties, an X-ray for PCB inspection is utilized.

Benefits of X-Ray for PCB Inspection

Quick responses at the beginning of product development allows the makers to take restorative steps to improve quality and also motivate a favorable brand name.

Designers will certainly have the opportunity not to improve defective components, minimizing unneeded expenses.

The x-ray makes it possible for inspectors to recognize a series of possible problems on the printed motherboard and recommend specific corrective actions.

- Country: China (Mainland)

- Address: F2, Building 10, Huaide Cuihai Industrial Zone, Bao'an, Shenzhen

- Contact: Jackie Tian