Sleeve And Socket

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

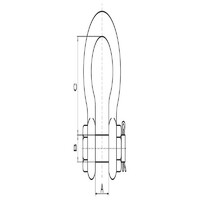

Wire rope crimps can be combined by pressing sleeves or cable joints. The pressing sleeves mainly include S505 steel pressing sleeves, aluminum pressing sleeves, stainless steel pressing sleeves,

etc. Wire rope slings of different specifications and standards can be customized according to customers needs. The tying method of wire rope rigging has undergone three reforms, from inserting,

aluminum alloy pressing to steel pressing. For most European countries most of them use steel press sleeves. The Flemish steel press sleeve is the most advanced way of knotting. No matter in terms

of aesthetics, durability or safety, it cannot be achieved through other ways. It greatly improves the working load efficiency. The working load efficiency of ordinary insertion is 50%, the

aluminum alloy press sleeve is 60%-70%, and the wire rope crimp sleeve can reach 97%-98%. Meanwhile, we currently supply 1000 tons, 1500 tons and other specifications of the steel pressing

machines. No matter wire rope sling components and rope slings, we have capabilities to offer you ideal sizes and quantities. Our quality department are also equipped with large-scale tensile

supporting equipment for inspection and testing.

S505 wire rope swage sleeves has different effects according to the grade of the wire rope. Compared with aluminum sleeves, S505 sleeves has much higher tensile strength than aluminum sleeves. Take

5t steel wire rope aluminum sleeve as an example, it can only reach about 75% of its work efficiency, but the steel sleeve can reach about 93%-97%.Therefore, steel sleeves not only perform great

advantageous from its aesthetics out appearance but also its inner superior.

Advantages Of Steel Press Sleeves

The rigging produced by steel wire sleeves has no end leaking out which does not hurt the hand.

The unique design of the steel sleeve makes it easier to extract the wire rope from one end.

The steel swage sleeve improves efficiency of rope knotting.To guarantee a safe operating, a a smaller diameter wire rope also be recommend thus save the user's expenses and make the operation

easier.

The rigging identification tag remind the operator to use the rigging properly.

It can be used in low temperature. all products share consistent and reliable quality assurance which undergo 2 times working load test and 5 times working load destructive test for 2% products.

Quality certification according to customer requirements, such as CCS and ABS certification.

Equipped with different tonnage facilities, for instance,1500t press sleeve machine, and tensile machine with breaking test load capacity up to 500t.

There are many lifting equipment manufacturers, but we are one of the best choices for you.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia

- Founded Year: 2005

- Address: 8-3, A Tower, Xiexing Building, No.59, Hongjin Road, Yubei District, Chongqing, China

- Contact: TITANSUHE TECH